Can you recommend any belt tensioners? This is something I seem to struggle with is belt slop and makes my prints come out smaller than I want

I picked these up in May and they’ve been great.

I’ve been watching quite a few videos about that shapr3d. I might have to try the free version for a bit. But I don’t have the Apple Pencil for my iPad.

@SgtAwesomesauce what bed did you switch to? I have a Ender 3 V2 with the factory glass bed and it is not even or uniform at all.

I am surprised to see this. One would have thought it would a much better solution compared to the older bed type.

I have the older Ender 3 Pro, and I ended up purchasing a Creality glass-bed to use instead of the flexible magnetic bed. It helped a lot, though it’s almost impossible to make it fully perfect, because of the 4 point adjustment system. It would be better if it was 3 points instead.

There is a company that makes a 3 point and a better hot plate but idk if I want to spend the money.

My bed was almost unusable before I got a bltouch

I don’t have any experience with what I am about suggest, so it might actually be more of a question, than a suggestion.

It seems like it would actually be a better solution to invest in a controller/motion system with “surface measuring system” that corrects for the unevenness and slope, rather that buying an expensive manual adjustment system, you have to keep an eye on all the time…

WhamBam FBS. For the few prints that I did on it before my main board went kaput, its really good

I’m just keeping it functional at this point, and I’m going to buy the Prusa XL. I’m on the wait list for it, so.

That’s the whole point of the bltouch.

Not only did I misread his comment, I didn’t look up what BLTouch was.

Yeah, a BLTouch is amazing. Truly an innovation.

It seems super helpful, but the idea isn’t really new. It’s been used in various CNC-machining for a long time.

Have you seen the recent This Old Tone Video, where he is using surface mapping on his CNC-mill to easily engrave 2D patterns on 3D surfaces?

Except that’s where the bltouch iterates. rather than using a strain gauge, it uses a hall-effect sensor to detect movement in the probe pin, which means you’re not risking damaging the probe or the sensitive bed surface.

I understand that. I was just pointing out, that the idea and function of surface mapping wasn’t a new idea.

Regarding the Hall effect sensor. It’s purposefully not used in machining, because of it’s many potential ways of interfering with the signal measurements. Being it the material or the electrical noise from big motors etc.

One could even use a digital Vernier scale- like system for diction and probe resetting,

interesting

Oh yeah, hall effect sensors really only work on a 3d printer because the EMI is much less

Even then, I’ve encountered some strange behavior with mine if I try to heat the hotend and take measurements at the same time.

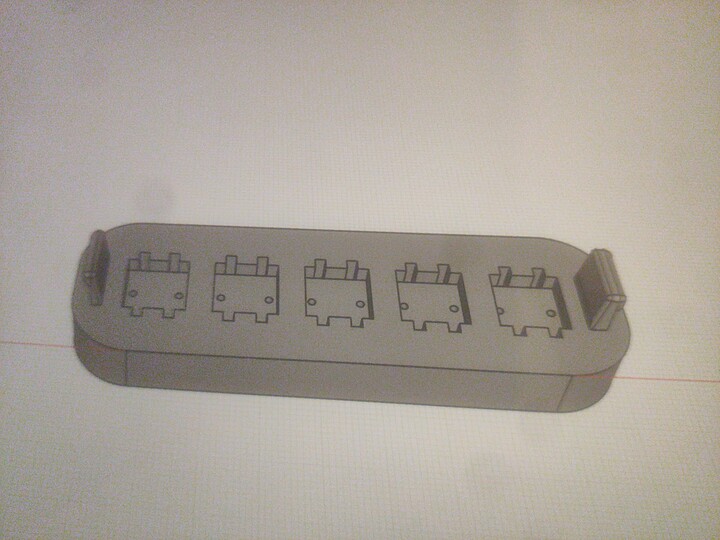

Needed a small case for my 5yo’s build and since I wanted to reuse parts it had to fit a full ATX and average mid performance GPU. It also needed to be quiet!

You know the rules, high power, low cost, quiet, pick 2 (if your lucky). I dug around for weeks looking for a decent SFF case and none fit the bill. They either uses SFX or ATX PSU’s which require a mATX motherboard. They also focus too much on fitting 3.5" diskdrives which is a waste of space in a modern general use and gaming PC.

So rather than spend $300 on a high end small case, I spent a bit over $100 and built my own.

All done with hand held tools and some clamps since all my big power tools are for wood.

Ok but real talk that looks pretty sweet. What games does your kid play?

80% Minecraft, 10% Super Tux Racer, 10% GCompris