no mixing metals as much as possible either aluminum or nickel (nickel plated) copper would be a nightmare with using aluminum finn’d block

@mutation666 the block was the only microfin’d aluminum block wayyy out does the china Cnc blocks

i plan to hard tube but that is set aside for v3

aluminum needs to almost near melt so you weld or braze aluminum to join parts.

thermal epoxy or really really tight machining is the normal way to attach aluminum fins

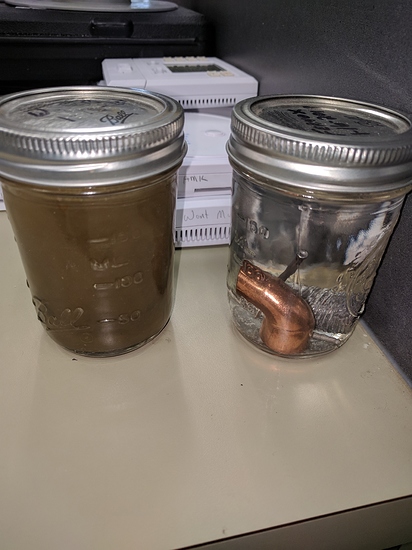

anti corrosion fluids like f1 @Adubs recommended in this thread might help and maybe a silver coil anode

This is our home made fernox f1 display.

Shit works. It’s been sitting for over a year at least.

edit date on top is 1/16/2017.

http://www.surmet.com/technology/alon-optical-ceramics/index.php

well its aluminum i really really want some

aluminium brazing is a bit of a pain if you are not used to it

4/10 would not recommend

brazing is hell i know i’m not the best but i can get the job done

have you brazed aluminium before? You need different flux. just so you know

Edit: Just went through the thread again, looks awesome so far by the way

only 2 times with help now its me on my own alot of this thread is me learning on the go haha

I really want to do a custom steampunk build, with copper tubing for my next rig upgrade, or possibly with my old hardware, as creating the case will take some time. This thread has inspiried me!

i have a idea for some “steam punk” builds like alot of acrylic work and more brass +copper like copper pipe brass fittings and a lot of uv or green (the old timey green glass) and one of those lighting touch boards

with a “vape” for a steam effect can be more like a smoke machine

that’s all cosmetic though,

Very cool idea.

I have seen some cases that I really like that have gages, switches and old school indicator lights. I really like this aesthetic, along with the copper.

unless your really good with a hobart tigmate!

welding aluminium with a tig is the best way too go but you really need a deft touch with it.

as a welding instructor Ive got a lot of experience with it.

That’s actually good advice. However, if you don’t have a TIG welder already it does not make financial sense.

First off: Brilliant thread! Kudos to you for doing this!

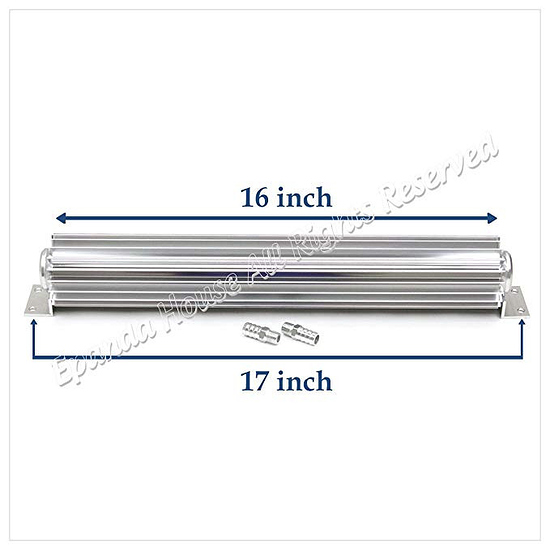

Those cylindrical coolers give me an idea…

What if you hade them encased and then pushed air along them from bottom to top? Basically like you planned but with some acrylic sheet to make sure air moves in the desired direction.

i see no boat sawn in half

doable but the overall goal is noise reduction adding any fans really would add more noise. the only moving part should be the blades on a water pump for this build