Except those coolers were basically the same as car radiators. idek how I’d mount it much less power it.

well on g5 aluminum the mobo and such is 3 or 4 mm above the aluminum shell so fully removing everything mounting rads with bolts and nuts cut some holes for tubing and find the “fittings”(place to run water out of the cold plate" and connect. I’ve taken a few apart for larp armour and that “tv head cosplaything” with a “newer” crt imac and g5 shell as a body. it would look cool! sourcing one should be ez like 50-100$ depending on the condition.

or if you don’t want to remove the entire system, you can do a small cut for just tubing and use thermal epoxy to mount the rad(s). looking at the default g5 liquid cooling and the tdp maybe 3 of the rads or more to get this to pull off. mixing metals would be the real spooky part. dont know what the cold plates are made off and if its solid or plated or what the tubing is made from. so for long term i would make or find some cpu blocks that don’t mix.

I was going to post about mixed metals and blocking microchannels when I realized I’ve never water cooled since its a pain in the ass to do.

I do like to live vicariously though others

Please share

thanks! im very spooked by that I know my loop is all aluminum but the alloy is a conundrum to me so anodes to help prevent it plus its mostly on the fins in waterblocks, tight places in rad’s and pumps i fear mostly. because there’s no mixed metals making direct contact like aluminum block cover on a cold plate i’m pretty safe on that but only aluminum alloys for the loop currently. am 4 glasses in will eedit later

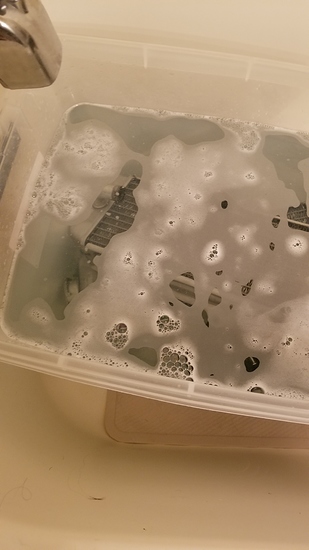

There’s alot more soap than I thought I’m gonna need to shower them. Damn there’s alot of soap no more oil though! I need to get 5/8" tube now and some aluminum “T” fittings if I find some fittings this may be tested in a passive loop cuase that tubes ID is huge I totally want to see this in action! More to come

finally in from Korea the “am4 size water-block retention bracket” its just a re-branded Intel bracket from the 2003-5 era parts you can find these for like just shipping cost like 1.40$ usd for diy projects this is nice to Have. it does fit am4 like just barely!

test fitting the block. waiting on the rads, aluminum plates, brazing rods, case feet and mother board stand offs sooooooooooooooooooooon tm!

testing the fit seeing where the tube is going to be I’m going to get some glue to seal the tube to the block because of the angle I do not want the tube to lift up away from the barb and leak

Here is the loop ready to go all I need is some ram!

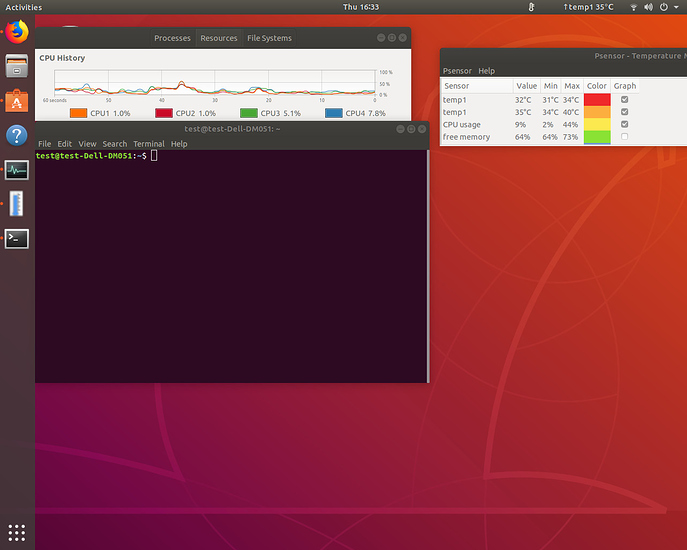

I am hoping for 35c idle on one of these rads but I expect worse with this water block I bet I can get better temps with the ekw block… Sooooooooon!!!

Here is the loop ready to go all I need is some ram!

I am hoping for 35c idle on one of these rads but I expect worse with this water block I bet I can get better temps with the ekw block… Sooooooooon!!!

eck switching from mobile to desktop messed with my post eck

With in a few minutes it got to 39c on the CPU and 31.8c on the loop

About 10 minutes in and 40c cpu and loop 32.6c

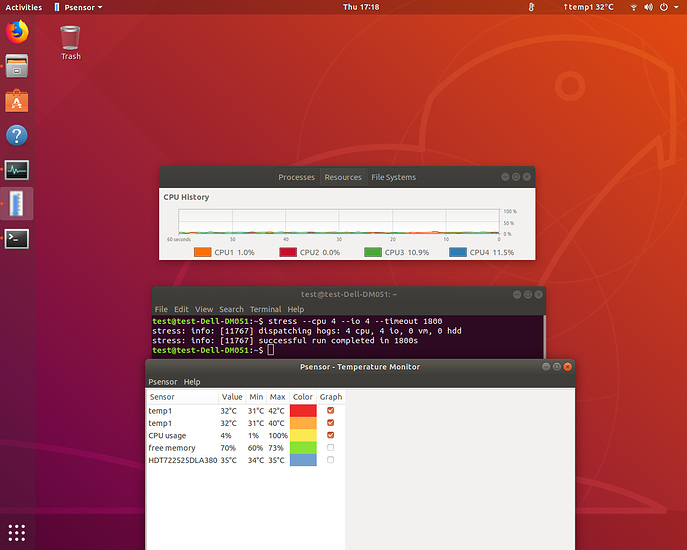

CPU stable at 44c dropping to 43c every so often loop 35.3/35.4c! So far all is good I want it almost ambient temps so 3 rads will be used. Will post screen cap when 3 hour run is over. Now I’m thinking of getting a passive cooled psu… Hmmm…