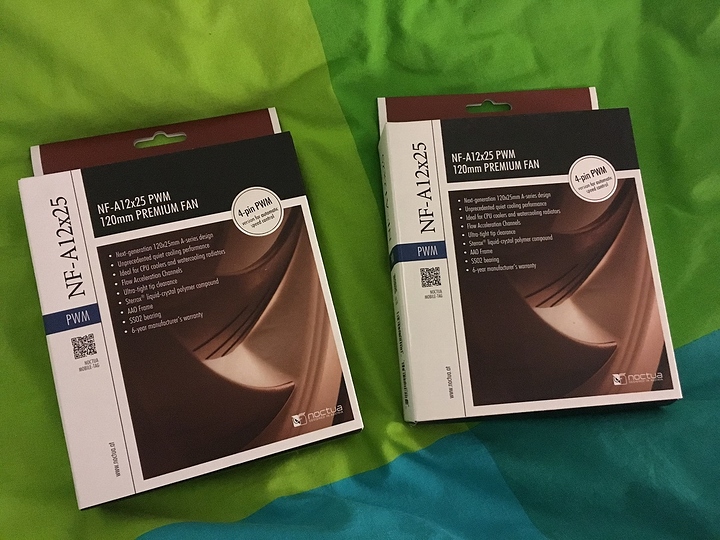

Update time! I blew some money and ordered some new fans. Two Noctuas are going at the front of the case to push the air inside of the case.

Here they are mounted to the fan shroud.

And inside the case

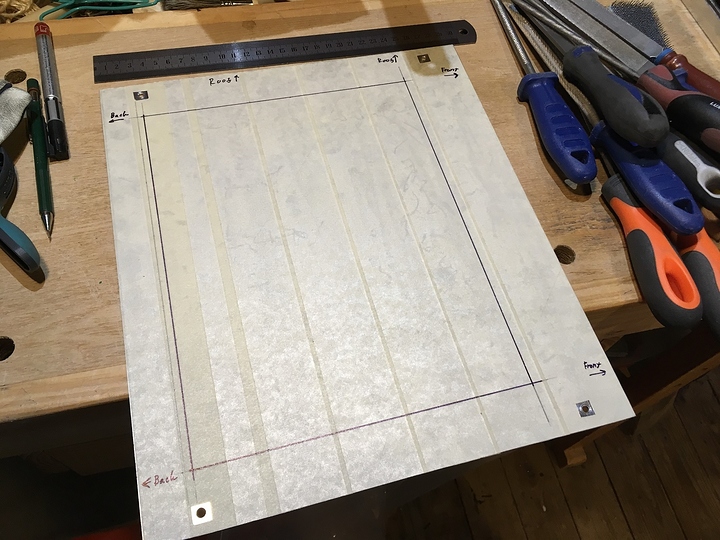

I also took measurement for future reference, if/when I upgrade the GPU. I could theoretically fit slightly longer card if I use slim 120mm case fan, but IDK, I rather try to find short GPU. Current 1060 is going strong so I don’t have any reason to upgrade this yet.

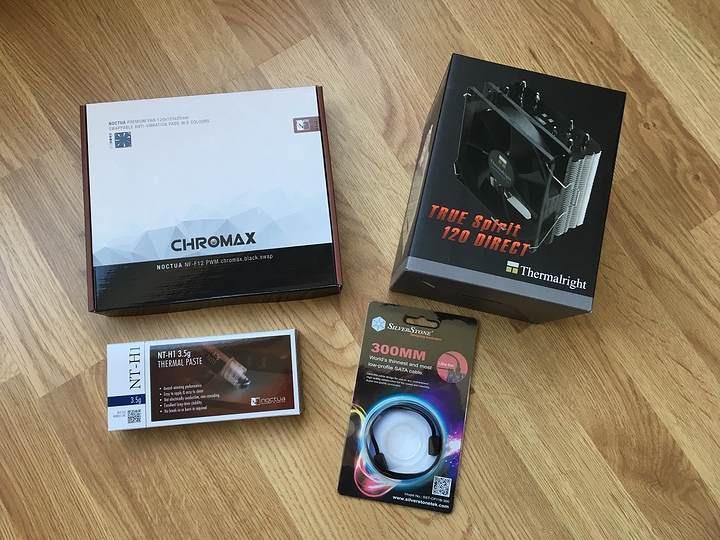

I also bought new cooler for the CPU, which caused some problems for me. More on that below.

I decided to go with Thermalright True Spirit cooler. Specs say it’s height is only 141mm while still using 120mm fan. If my measurements are correct it should fit inside the case. WELL GUESS WHAT, MY MEASUREMENTS WERE OFF BY ONE FUCKING MILLIMETER!! RREEEEE!

Oh and I got new Noctua fan for the cooler. Didn’t even try the stock fan that came with the cooler.

Cooler also supports AM4, so it does not matter if I end up using Intel or AMD platform when I upgrade, I should still be able to use this cooler. I would love to use Scythe Fuma cooler, but its height is 149mm, and I don’t think I’m clever enough to make room for that.

I could also use tower cooler that has 92mm fan, but meh, I rather use 120mm coolers since they are quieter.

New cooler and Schythe Mugen 3:

True spirit costs only 35€, and it kind of shows. Then again I’m not going to overclock my CPU so this should be able to keep everything cool.

Here’s short video where you can see the hardware layout and untidy cable management better.

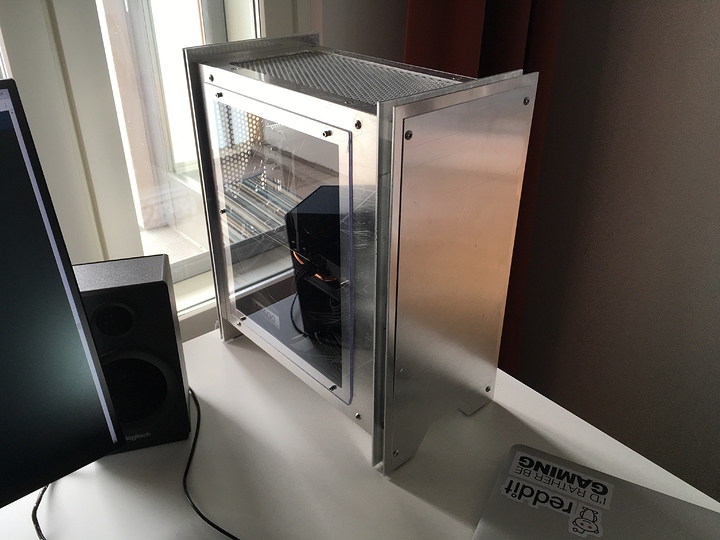

And since you already saw the spoiler, new cooler was 1mm too high, so I had to put some washers between the case and the side panel. Since the side panel is made out of 2mm thick aluminium sheet, I stared thinking if I could add little more space under the side panel by cutting a hole to it, and then adding new extra plate on top of the hole? This would create 2mm extra space for the cooler.

While I was buying some stuff from the hardware store, I found this: 300x300mm and 2mm thick polycarbonate sheet for 5€. I thought this was perfect for my case and I could use this to make a side window. I’ve never been big fan of side windows in cases, but I thought I’d give it a try anyway. I can always make new plate out of aluminium if get bored at having the side window in the case.

Oh and the sheet is clear, not red. Sheet just has some protective film over it.

Hole cut

Since polycarb sheet was 300mm by 300mm, I only needed to cut little bit off from one side of the sheet.

And fastened to the case.

Since I didn’t have any idea how to cut polycarbonate, I used normal jig saw that I use when cutting aluminium. This wasn’t the best method since it left some small cracks to the side. Good thing is they are not that easy to notice, but I’m still going to redo the part again later. I could even try to find some tinted polycarb sheet.

Finally some money shots for the case. There are some small things like redoing the window still left to do, plus I have to finish the case surface somehow. So case is not finished yet, but pretty close!

I will update this work log when I have something new to show to you. Until then, stay beautiful.

Oh and friendly warning to mods/admins: I have no idea when I will have next chance to work on this, could take more than 6 months (hopefully not), so I might have to resurrect this thread later. Some crazy stuff going on right now.