thats a good idea i'll try something like that with the end of my tubing. I am still using suction but with a much larger pump.

Im interested in how it works out. I cant see how you can't get a win with some tom foolery and chewing gum

i'll keep ya posted. After this is working its time for the solar half, that parts pretty straight forward get idk maybe a 100watt or so 12v panel and a charge controller, if it can't charge the battery enough wire a second panel in parallel

I might just try reducing the inch and a quarter pipe down too 1/2 inch with adapers and see if that works, that might put too much strain on the pump though

Success bitches!!! The PVC was not damaged. The problem was the pump although self priming cannot self prime from 25ft straight up. I got it working before by sucking the water up with my mouth (turns out I suck hard) but two problems with that first I don't wanna suck on my well all the time and two if I get an air bubble it loses its prime and the water drains too the bottom of my well.

I solved this by getting quarter inch diameter tubing priming it by sucking up water in a bucket cutting the power to my pump wile putting my thumb over one end of the tube to hold the water up much as you might do with a drink straw, then running the tubing down my well and powering the pump back on.

Doing this this I achieved a reliable stream of water.

I also attached my little pump after my big one just cuz and it gives me a powerful spray wired too the battery in parallel with my big pump.I even dropped it in the bucket and it did not short out, its actually a pretty robust pump for what it is. I strongly suspect it would work very well for water cooling ran at a lower voltage so it would put out less water and run quiet.

With quarter inch tubing at each end of my big pump and the little one at the end it fills a 5 gallon bucket in about 5 minutes. I pumped 30 gallons just to experiment and both of my pumps ran quite cool.

I have tubing that is a little under a half inch I plan to try this with and see if I cant up my flow rate, when 1/2″ pvc was working it could fill a 5 gallon bucket in less than a minute. I know the small tubing after the pump is an unnecessary bottle neck but I may not be able to reliably pump with larger tubing in my well, have to experiment and see. The small pump may or may not be lowering my output by drawing amperage the big pump could be using or just from its low flow rating. My big pump has no check valve at all so I plan to add a valve that I can close so it will hold the prime. I think it has a pressure switch so I should just be able to vale the end of my tubing and the pump will turn off automatically when I close it.

Alright now I need a little help experementing with larger tubing I learned some things.

My big pump can't exactly deal with the 1/2" tubing on its own what happens is as soon as it gets fully primed and going good it quickly out pumps the water faster than the recovery rate of my well. If I hook my smaller pump too it it can reprime the big pump and as soon as my well recovers in a matter of seconds its back up too full flow where it quickley out pumps the well again.

Now want I want to do is add a variable speed controll too my pump so I can dial it in to the point it pumps just below the recovery rate of my well.

Not under pressure my pump draws 7.50amps and can output pressurized up to 60psi where it draws a maximum of 15.50 amps at 12 volts. These are specs taken from its data sheet

Anyways what I want help with is the circuit to slow my pump a little, could I get by with just hooking up a potentiometer or would I need sometime a little more involved?

Run water backwards through the system to prime and get a check valve. If you could put the check at the bottom of the well that would work best but anywhere might help.

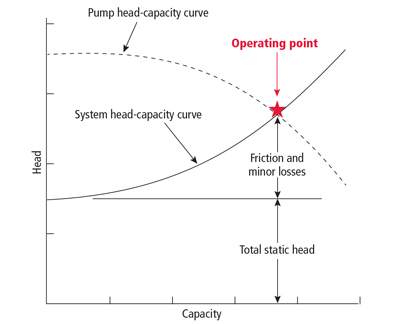

put a ball valve on it and close it partially to increase head, this will in turn slow down your GPM.

It would have to be a big pot to handle that kind of load. If you're looking to reduce current your best bet is a smaller pump or a reduction in voltage. Maybe see what she does on 6v?

If I put under pressure it will significantly increase the power draw.

6v could work and a simple Voltage Divider Circuit could work for that. I have a wall dimmer switch though so I'll probably give it a go and see what happens

Pulse Width Modulation?

You probably don't want to vary the voltage to the pump. It's rated for it's peak efficiency and if you brown it out by varying the speed it will die prematurely. Submersible pumps and variacs don't talk nice to each other. Read back to my earlier post. Put it on a timer and pump it into a storage container so it can run as electrically and mechanically designed.

I have a timer used for hydroponics that has an optical sensor as well as cycle timer. you could set it to only pump every ~9 hours when it is dark so it doesn't pull when the batteries are charging and dischrges when it it cooler out.

I agree with @slappy_D0 on the voltage for the pump. That's a no-no. The pump rating is what it is.

Either leave the smaller tubing to artificially induce pressure loss (at least to a degree) OR wire the pump to be "on" for X minutes, than "off" for Y minutes etc.

Either option is probably not as bad as messing with the voltage but either will definitely shorten the lifespan of your pump. The second option is not as bad as system damage induced pump cycling, but the constant on/off operation is still a strain on the components...

Increasing the friction loss (by using a smaller diameter hose for example) will reduce the flow but increase the pressure... your pump will probably have to draw more current to compensate. Which equals heat and fatigue on the components.

The difficulty of your scenario is that you have:

- a low yield well with...

- a deep enough water table that a smaller $20-30 pump wasn't able to handle (from the surface, at least), and...

- you must pump from the surface, which means sucking - and pumps aren't designed with that in mind.

Have you considered drilling one or two more similar wells and connecting them to the same pump? I've never seen this done though but it's an unusual situation...

This is only true if the duty point on the pump is the same so its increasing amp draw to compensate and do the same work. If the current goes down there will be no added heat and thus no extra wear on the windings, etc. Were trying to change the curve entirely since the pump is oversized. If this were an ECM controlled pump or one with an external speed control then obviously this suggestion of reducing voltage would be a terrible idea but this is just a dumb pump. At my work we sell pumps that have resistive switches as "dumb" speed controls. Obviously theres more to factor in about the pump when considering that but my point still stands that as long as were not trying to meet the same duty point it should be just fine.

This is all assuming of course that pump will even spin on 6V. It may not do anything at all. Or it could spin too slowly to do anything useful.

I respectfully disagree. Pumps are designed to create a pressure differential. Though its true you dont necessarily want to "suck" due to cavitation but at a low enough RPM on the pump I dont see this as an issue. The main issue is priming and keeping it primed. Thus a check valve and probably an auto air vent is truly a must have here.

To be fair I dont have experience with wells or running them from solar applications but I do work in the hydronics business. Basically what I'm saying is I'm not a complete idiot, some assembly is required.

At any rate i've had another thought that could be even simpler, a small bypass loop that just feeds back to the pump to keep it from:

- Out pumping the recovery of the well.

- Pumping way more water than is needed.

- Running at higher current levels than desired.

- Dead heading and causing cavitation.

You guys tell me what you think.

EDIT: Some of the things here are not needed but rather are "nice to have" things, like the hose bib, and isolation valves. This is merely a best case scenario in my head.

Haven't read through everybody's replays yet cuz I'm at work but wanna add some info. The pump I'm using is a remco 5536-1c1-82b-sb. It goes for more than I payed online so at least I feel good about that

I do believe we're overthinking this, but it is fun in the abstract. I'm the guy who would just make it work one way or another hands on. The pump is overkill for the original goal. I still believe to use it at full power and rack up storage for your water needs. A check valve and a filter and you're done.

With top storage you can drain back priming at will...

You're most likely right about this. But I thought about it and I've actually talked about this with a guy who's a mech engineer. Basically the degree to which you can "play" the pump curve depends on the construction and more importantly, the tolerances and impeller design. To be honest, I have no idea about these small DC pumps and how flexible they are. So I gave that advice just because it's something that I would personally not try playing with (because I'm not sure about the pump) before trying other options.

If these DC pumps are really capable of that, then that's awesome. I'm gonna get me like 5 of them.

I agree, but the engineers design them to be situation and need-specific. And people are usually interested in what happens and what they need downstream, on the outlet. I didn't mean they are not capable of sucking, but it's not a "primary" characteristic in the sense that power rating, flow and pressure are. Sorry if I can't find the exact words, English is not my first language. From what little experience I have, I've seen two different types commonly used for wells:

for high flow: Cylinder-shaped and submerged. It alleviates a plethora of problems, one of which is, you guessed it - priming.

for lower flow closer to the surface you can get away with a mid range surface bore pump (or whatever you call it, I see some call it "double drop pump") with one of those ejectors to increase the depth from which you can suck. If it's for household use, it's usually the type that comes with one of those bladder things.

I like the drawing

Also, about the check valve - were you thinking about a foot valve or a different kind of check v.? Cause a foot valve is ideal for this situation. I would check the system without buying an air vent first. Screw that, an air vent is never a bad idea. The loop idea seems wasteful, though  Plus I have never seen anyone do it like that. DO IT!

Plus I have never seen anyone do it like that. DO IT!

I'm having fun. And I can't wait to see what Frankenpump solution comes out of this.

You do make a good case for it. You could even have a float switch trigger the pump like a toilet system...and you wouldnt need an air vent like my idea has if it was open air.

It really is wasteful but since it was solar anyway I figured it didnt matter.

A foot valve would probably be ideal. Any kind of check really. The problem is getting one down there so a foot valve is probably the best bet.

So combining ideas here, I present REV2

How exactly does the "open to prime" valve prime the pump in this case? That part's supposed to be just for flow regulation to match the well yield? Also, priming is only necessary once per season (if you drain the system for winter preparation) with a foot valve, right?

Thats why a battery...all the power all the time....it just a matter of how long it can run. Also a trigger on the barrel would be a nice not overflow measure.

Idealy you would have the barrel filled with a normal days light and then kick back and have a few drinks the rest of the day. That way you remove the one timer and just keep the barrel full err topped up.

It should fill most of the system to the level of the water in the storage system. So long as the pump is below the level of the water (which I did not show correctly, my mistake in my haste to slap together some lines) it will fill the pipes while the pump is running.

More or less yes, since the pump seems to be moving more GPM than the well can supply. You get the idea I think?

Or if for some reason the system air locks and the pump cannot seem to make up the difference.

Thats what the float swich is meant for.

something like this guy maybe?

Ah, yes that would work.