So a few monts ago in the deep snow I had an emergency run into my town. I went my normal route, but it was a blizzard so I was going about 20-25. Where I usually drive had some houses going up (BTW its the worst place to put a house, in the middle of a wide corner at the bottom of 2 hills… You’re asking for a drunk to come piling through your living room window). However, someone decided it was a great idea to put a neon white blinking light on top of some shitty trailer so I ended up in the ditch because it caught my attention. I bent my control arm in my truck but it coulda been worse. If I was going any faster than I was I woulda hit a pile of boulders that was 8 feet in front of me.

Anyways. Now you have context.

Heres my truck.

2000 blazer with every option on it. My heart sinks every time I see the front tbh but I’ll get that all patched up soon enough.

So the predicament here is I don’t work on vehicles at all and my dad + his friends have never done this job before. So pretty much flying blind here. I know other models are sorta the same, or are the same, or are close enough to compare to, so I’m confident I’ll be able to wiggle it out.

First thing was disconnecting the stabilizer (sway bar?) from the front.

Well that didn’t work.

Aight.

So I started cutting it with a big grinder and one of my asshole cats decided to use me to jump onto the truck. Then this happened.

Tried to see if I could grind it back smooth, but decided to take it slow with an air grinder instead.

Took about a half hour more but whatever I got the thing off.

Next the shock.

I didn’t have a wrench the right size on hand.

Eh works

Next loosen up the tortion bar (always count your threads)

VS everything else, this is the bolt that took the most work. I don’t know why.

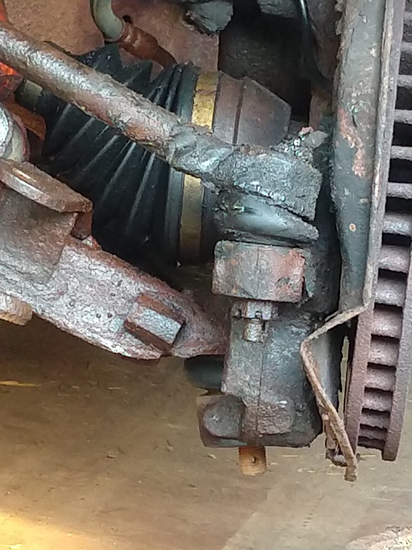

Then trying to get the bottom of the knuckle loose enough that I know I could MAYBE pop it off?

smacked it with a hammer a couple times after that cotter pit nut was loose, and I’ve hit it with Kroil a few times, nothing indicates its broken free yet though.

Last thing I did was the pivot bolts. Well, the rear one anyways.

The front one was annoying because it was behind the stablizer bar up front. Had to wriggle a socket in there and basically just kept shaking shit around till it lined up.

Yes I know theres an oil leak the oil pan gaskets need to be replaced.

So the over all goal here is to basically just have the thing fall out. According to things my dad has read, you really don’t need to rip the knuckle all apart, but just… loosen it. And thats the goal. However theres still stuff that I can’t quite see how it goes together, and our repair manuals don’t show bullshit.

SRSLY need to teach car people how to properly document shit. Its like teaching BSD people that the build directory could be stored on another drive.

Sigh.

If anyone could answer: do I need to pull the short axel out to do this all the way? Or should I take apart the hub and just deal with it? (I’d rather not)

The SA has some leeway in its placement and I can push it in quite a good deal and I think I might get the wiggle room I need, but I’ve still yet to work that front pivot bolt out yet. And its more than possible that with the weight of the A Arm itself the SA will just get shoved back anyways.

IDK yet I’ve been researching 4WD systems to make sure I can’t fuck anything up.

more later

/thread