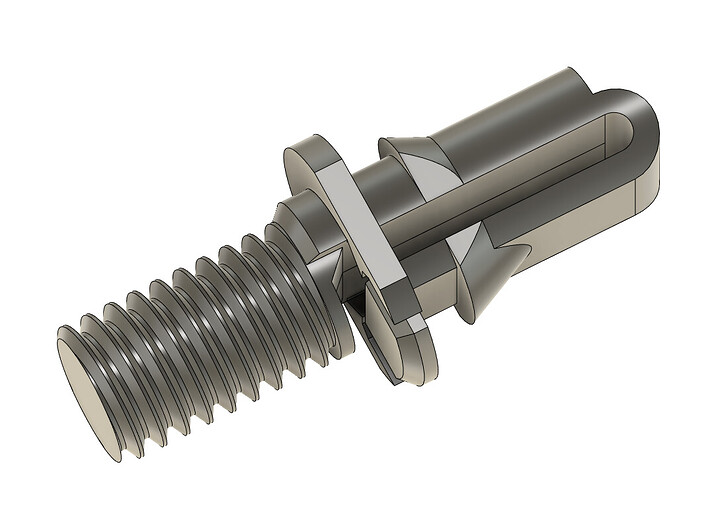

not sure I would trust 3d printed studs, but maybe…

What I use

and I am off to reverse ENG this into my design if possible.

I do have some concerns about weight capacity, the rails are rated to 75lb so I need the adapters to match that.

330lbs/per stud so figure 70% of that for a 3D printed version looking at maybe ~230lbs per stud if you are using a good CF Nylon for your prints.

yeah i was referring to PLA concerns not the Rack Studs.

well test print is going so we will see if this is any good.

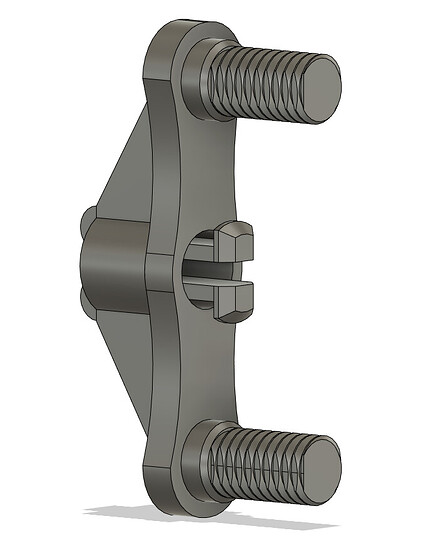

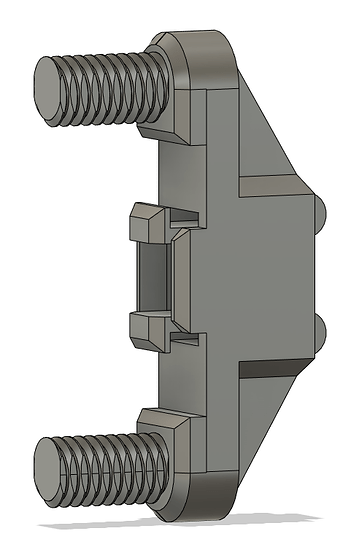

If its not strong enough I might reverse it and have 1 stud, and screw into the plastic with a nut or heat insert. Realistically the point of this bracket is to take the weight of the rack mount case and move it to the rails anyway. So no real need for 2x pegs.

so the threads work, but the resolution on my printer with a .6 nozzle is not really enough. I think we would be better off using a clip to align and hold it while then using traditional screws to secure. Plastic just cant compete with metal in this application.

If I do the stud, it will be for preventing the rails from sliding open but not for mounting.

Want someone to try it on a 0.4mm nozzle? I can give it a go on a machine with decent but not exceptional tolerances, should be fairly representative

im working on a 2 peg clip now that will fix the issues and be more printer tolerant. I plan to make it for both square and round holes, should be done with it tonight so I will update.

then I need to get back to the core design! silly side quest.

Also welcome!

I’ve been following this discussion for a bit and looking forward to the completed core. Right now I have a handful of machines just sitting on a shelf in my rack and was looking at doing something like this!

Big and Chonky! Just the way I like it! ![]()

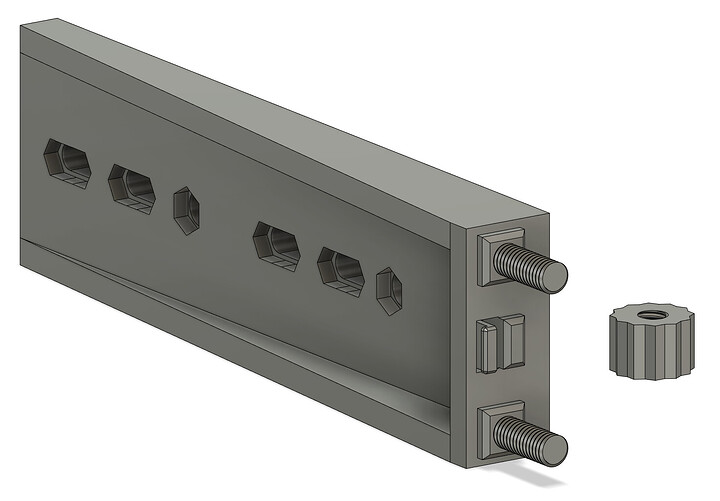

Rack Stud.stl (499.3 KB)

Nut.stl (534.2 KB)

Here are the Rack Pegs and the nut if you want to try them at a higher resolution. I print them flat with support on the build plate only. Turned out well enough to use on a .6mm nozzle.

Now with square holes:

Square Hole Stud Clip.stl (3.8 KB)

Square Hold Rack Stud.stl (465.2 KB)

FYI project stalled again for a short period because I ran out of Filament, and I got a larger format printer that I am assembling.

The goal of making this commodity sized (200mm) has not and will not change. I just wanted to upgrade to something larger and faster than my Ender 3.

What did you get to replace it?

Not replacing, but Im building a Voron 2.4 350mm. I wanted to a Bambo but their response to letting people install a custom firmware was the final nail for me.

I really dont want to spend money on something that I dont own, and that can have its servers just turned off in the future.

Yeah it’s a tough situation as Bambu seems to be far and away the best consumer available printer that is plug and play. Their lack of OSS support is extremely disappointing.

You should post about your Voron build here or in the 3D printer thread.

What kills me is that it depends on them having a website up where you can put in an SN to unlock.

Like… wtf just let people unlock, i bet they already lost more money trying to defend this shitty closed source crap (when they just modified klipper) from people like me who would have purchased, than the number of people who will mess something up, flash it back to stock and then try to claim warranty.

Great work!

I’ll be following this closely as I have been trying to find a 3D printable NAS case for an ATX motherboard for awhile.

I am having to redo the front support design because i found a flaw, but planning on working on it this weekend if I can.