I had an idea for a community project. I could provide hosting, infrastructure, project management guidance and some development advice here and there (frontend/backend if the backend is python or php or possibly go) but that's about it.

Maybe something @Devon would want to work on? He was always asking after fun side projects to do ;)

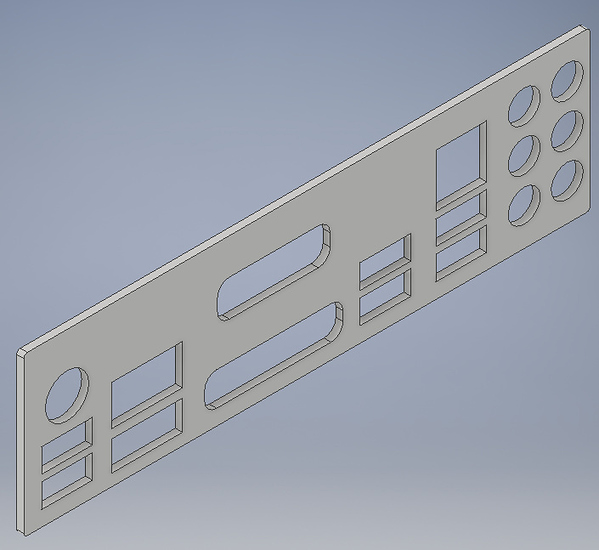

The project, probably could be done in a few weekend hackathons, is a website that generates 3d printable models of I/O backplates. Project Code Name: Back plate-inator

The idea would be to make a pallett (like a painter's pallet) of cut outs for a back I/O shield and do a simple javascript UI to drag and drop cutouts and arrange them on backplates. It could ask the user for their motherboard brand and model and store the layout for someone to use in the future.

We don't have a backplate? Fine, make one. Once you make one in the web UI we remember the recipe.

Could probably break the project into a few major features -- the database, the front-end UI, and the 3d model(s) which is probably just a scriptable openscad model.

It would be a labor of love, but probably a good college student project. Maybe someone in the community already has openscad experience, or otherwise has experience with programmatically generating 3d models.

The end goal would really be to just plug the level1 community.

I don't know how useful this idea really is but if nothing else you could color-coordinate your I/O shield. Since RGB seems to be scary popular despite no one asking for that.

Could also be interesting as a "meta" project -- actually do a project about distributed software development, project management, how UI/UX evolves, planning this type of project, testing, automation and deployment. So we could get a video series out of it. But I don't know that its worth our time (dev time) to do it entirely on our own. With community members doing most of the development though, it could be a really interesting "case study" project. And somewhat actually useful stand-alone.