Well here goes. I know I should be working on with my devember challenge, so for that reason I’ll show what I’m working on instead.

@anon54210716 suggested a while back I could try to recoat my old SteelSeries Sensei RAW mouse, and now since I’m spending time at my parents place where I have my father’s workshop available, I thought I give this a good old college try.

For whatever reason the spell checking is not working on my Firefox atm, so please excuse all the typos and grammar errors in this log.

Please note that:

- I don’t guarantee this mouse will be operational after I’m done with it.

- This is mostly just a test. I’m not 100% sure what I’m doing, but I’ll do it anyway.

I didn’t take any pictures how did the mouse look like before I started to disassemble it. Here’s a picture from google how did it look like when it was new:

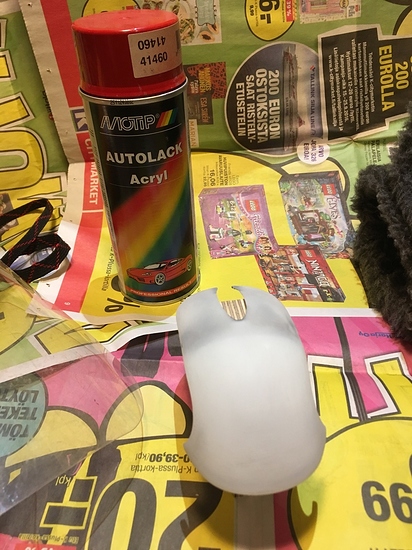

Mouse didn’t actually look bad, the coating looked pretty simmilar to that picture. But oh boy did the coating feel disgusting and sticky. So here I will try to fix this and recoat the mouse. At first I was planned to use some vinyl, but since my father has some spray paints here I might try to repaint the mouse. I know the natural oils from skin will eventually degrade the paint but I’m not too woried. I can always dismantle and repaint mouse again, or try someting else.

First I removed the mouse pads, or what ever they are called. Under them I found four small screws and once those were removed I was able to open the mouse. Side buttons etc. are attached to separate PCB and it was connected with small ribbon cable, that was not soldered to main PCB.

More screws and some platic clips held the top of the mouse together, and this is what it looks like when disassembled. I did clean the mouse wheel sonow it should scroll freely. There was a lot of dust and other gunk in scroll wheel assembly, so no wonder it was bit stiff.

I tired to wash the plastic pieces, but the rubber coating was simply so worn there was no way I could improve it anymore. So, sanding paper to the rescue! I used regular 150 and 80 grit sanding paper to remove the rubber coating from the mouse assemlby. You can see from the picture when I started to get that coating off.

The top piece of the mouse assembly was real pain to work. It took little over one hour to get that damn coating off. I managed to break one plastic clip that was in the top piece, but I hope I can still reasemble this.

And here’s how the top piece looks after intensive sand paper action later. I’ll see if the weather is good enough to paint this tomorrow.

Updates will follow later.