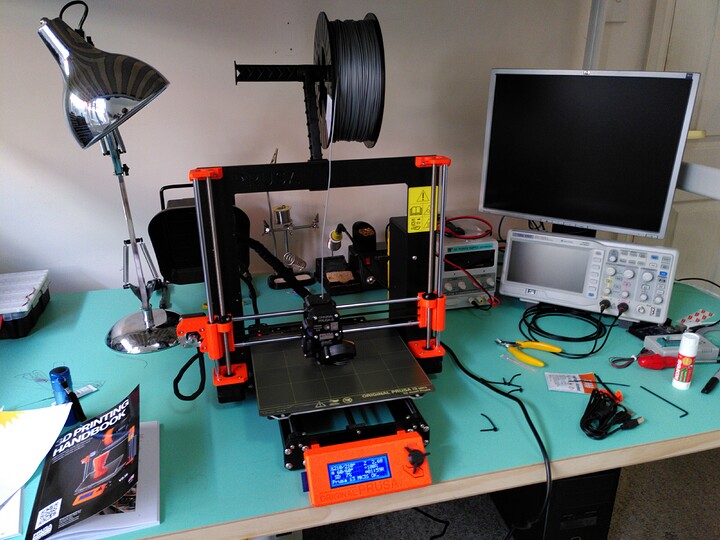

Prusa is certainly a good choice, mostly because they are the best of all worlds. They have a very nice product with all the bells and whistles you expect from a decent printer (E3D hotend, TMC silent stepper drivers with fault detection, auto bed leveling, removable flexible build plates which work with most materials, filament runout sensor etc.) at a decent price; thank low wages in the Czech Republic for that.

Also the founder Prusa was big in the early open source hobby printing space and this has carried into the company philosophy. All their hardware and firmware (also maybe their software, I’m not sure) is open source. You can modfiy the printer as you like, although this voids the warranty, just like a home built kit.

Another benefit of Prusa is that they are well vertically developed. They have their own slicer as well as materials, so there is no need to dig into slicer settings at the start which can be a bit overwhelming and frustrating, looking up guides on print settings and how to troubleshoot problems etc. This is the main benefit of Prusa, because they do most of the heavy lifting in their well made machine and preset printing profiles so you can get going straight away.

My first printer was an Anet A6 which I bought for £160 in 2017 as a poor student. It was pretty bad (I had to use gaffa tape to hold a faulty part together while I immediately designed and printed a spare part on it lol). The super cheap machines are deathtraps, live mains exposed wires and many stories of peoples house burning down. I spent way more money and time upgrading the electronics and extruder than it was worth, except the learning experience of essentially building my own machine up by gradually replacing all the parts, which is a genuine approach if you want to go in deep as a hobby or you have more time than money.

I am currently studying a masters degree in advanced materials and additive manufacturing (thanks in part to my hobby printing) and industrial additive manufacturing is a completely different ball game to the hobby space. There is more diversity and complexity in industrial machines e.g. Selective Laser Melting or Binder Jetting and sintering for producing metal parts, whereas hobby is pretty much limited to plastics and mostly FDM machines. All the cutting edge developments in hobby FDM printers are coming from the hobby space.

When I built my machine, print speeds of around 60mm/s were common. Now people are building custom core-XY machines which can go at 1000+mm/s, although this is in the ‘speed-printing’ domain, which picked up a lot since lockdowns because people didn’t have anything better to do. Thing is, having the best cutting edge machine is not at all necessary, just good enough and with the ease of use and quality to make what you want.

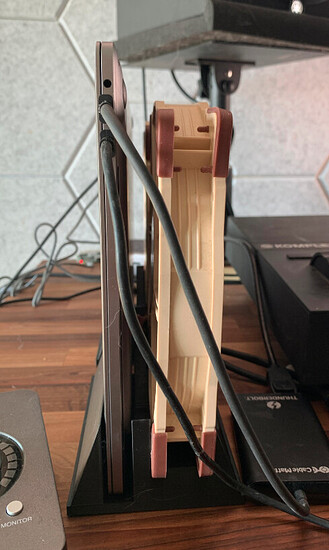

I got a Prusa Mini+ recently as a prize from a 3D printing design competition, and I must say compared to my custom machine, the ease of use and quality with basically no effort is a breath of fresh air. I recommend the Prusa Mini+ if you are on a budget since that is much cheaper than the MK3, but has most of the features. It is a bit smaller at 180x180x180mm vs 210x210x250mm for the MK3. I rarely max out my printer volume personally but it is a consideration. I have heard some people having issues with the mini, such as layer banding or clogging, doesn’t seem to happen with many machines and I have had no issues with mine so far.

There are many other Chinese printer manufacturers like Creality, Anycubic, Artillery and Elegoo who make lower cost I3 printers but without all the bells and whistles and open source but are generally decent machines with large communities for support. I haven’t been keeping tabs on the industry so I don’t know which exact models to recommend, hence why I default to Prusa which you can never fail with.

The Prusa Mini has a few limitations like being a bowden system so it can’t print flexibles too well (you could modify it to make it direct drive), and print volume. But as a first printer it’s hard to fault. If you find you enjoy 3D printing then save up for a Mk3 (or a bigger one to print the big stuff you were mentioning).