don’t they make pico PSUs that do all that for you but can accept a 19v brick?

Congratulations on the three features on big gaming/tech news sites! Deserved beyond any doubt.

Seeing that someone on here asked you to build them one maybe you could make this a side hustle.

don’t they make pico PSUs that do all that for you but can accept a 19v brick?

I adressed this point during the project, but an HDPLEX would have too big/cumbersome to fit. I would have need an elusive HDPLEX160 v2 that would have fitted convenently inside.

Congratulations on the three features on big gaming/tech news sites! Deserved beyond any doubt.

Seeing that someone on here asked you to build them one maybe you could make this a side hustle.

Thanks. Although there was some interest, it was silent on my side, never had any formal request. Would not have complained about this little side hustle.

Thanks. Although there was some interest, it was silent on my side, never had any formal request. Would not have complained about this little side hustle.

I think you can really make it. Surely now that you know the quirks of such a build you could almost streamline it, knowing where to trim the shell and add ventilation. Maybe even just selling modified shells could work too.

Just throwing ideas because I like your projects (didn’t forget about the Sega Genesis one).

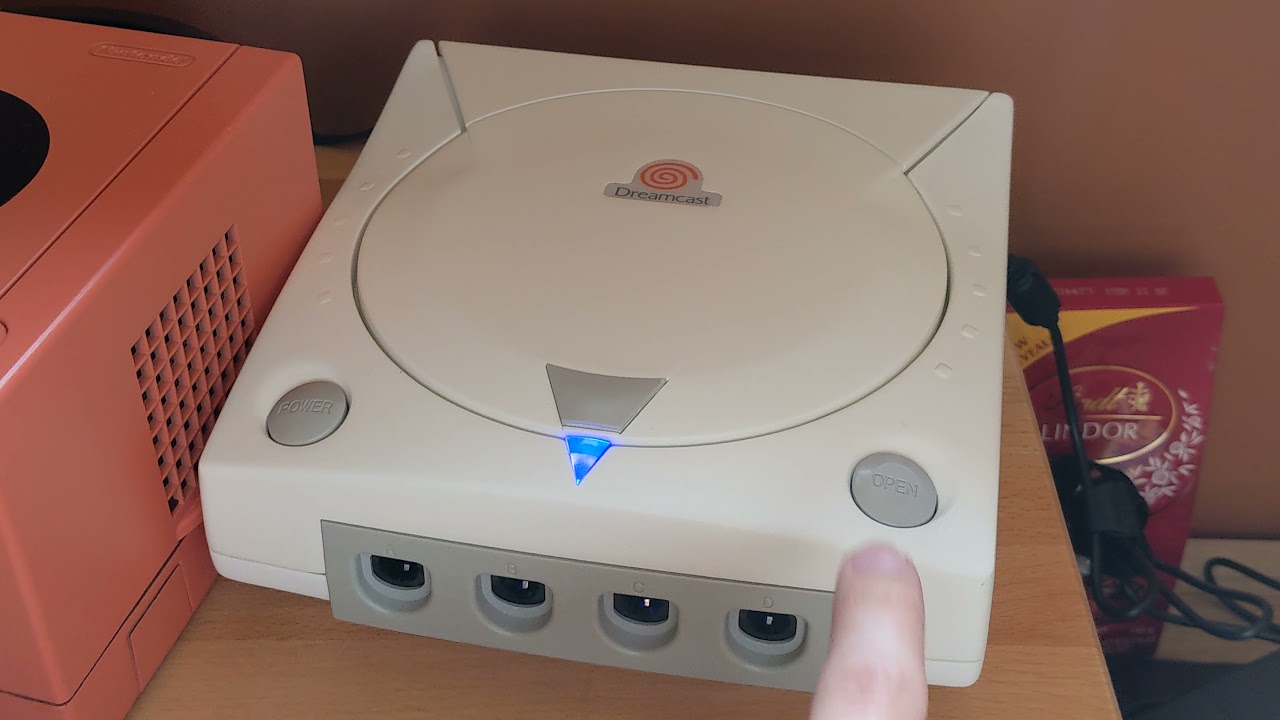

So I will complete the Dreamcast build, because I want it done even if at the same time I don’t want to spend money  Will surely run Windows 11 preview on it and maybe use it as a media center.

Will surely run Windows 11 preview on it and maybe use it as a media center.

Went for a cheap 3200g from ebay and have a deskmini x300 on rebate from newegg coming my way. Will buy also the ram tonight, but waiting a little more maybe I have an answer from a guy on kijiji with a set of ram at a really good price.

I have still the nvme ssd and noctua cooler from my previous build.

Uzume time!

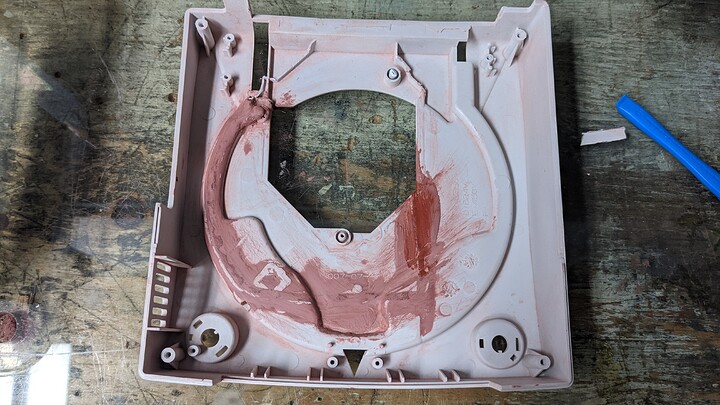

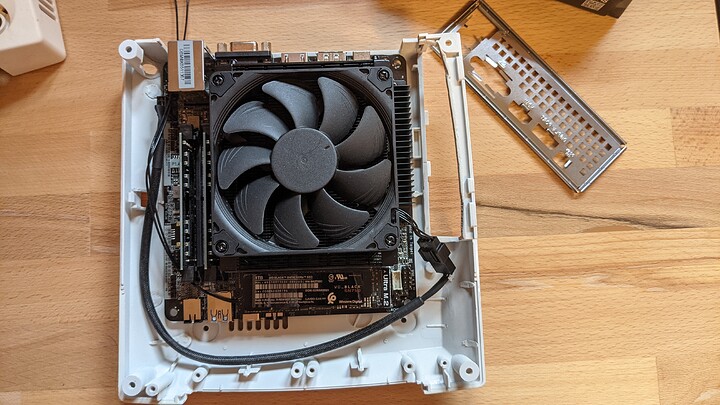

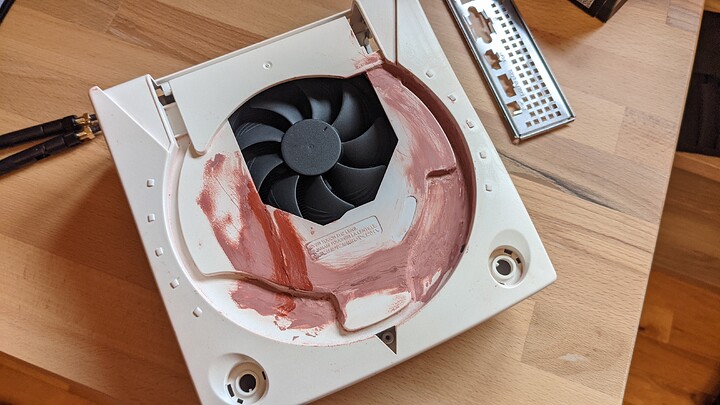

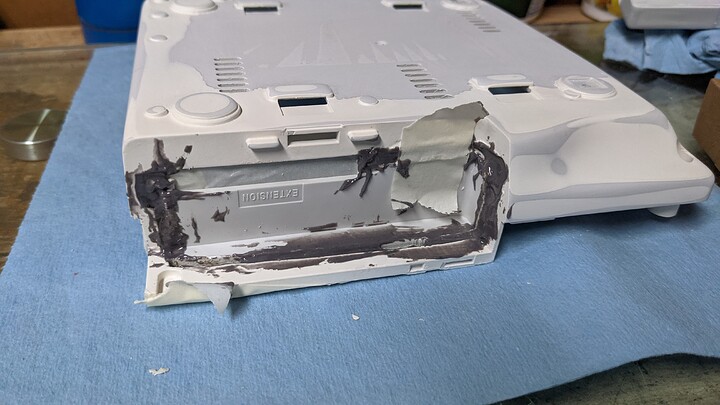

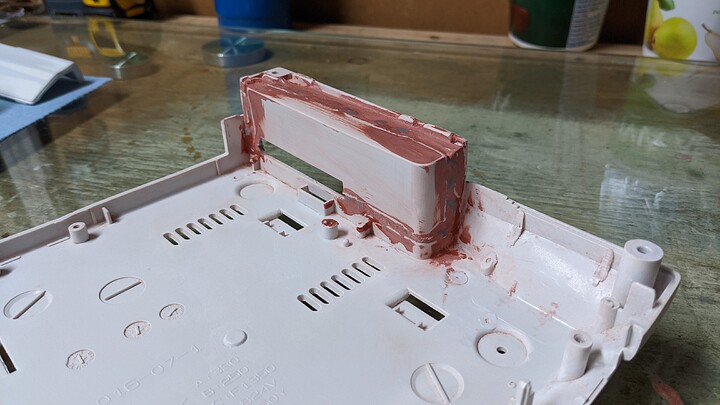

So you remember when I gutted part of the disk area so the cooler would fit with itx board? Probably not, but I did, and I didn’t like that I gutted the shell like that. So after a small fit test with cardboard and my cooler, before even receiving the actual mobo to confirm everything would fit well, I just went ahead rebuilding it  Not finished but going well.

Not finished but going well.

(Oh and I decided I just gonna repaint the whole thing again)

And received all the components I needed already. The logic here is that I wanted to spend the least money possible, so 3200g is a used one, the x300 was on rebate on Newegg, and I gonna complete the mail-in rebate also, and the ram (16GB, 2400Mhz, CL14) was on special (the 2666 also but no more stock online).

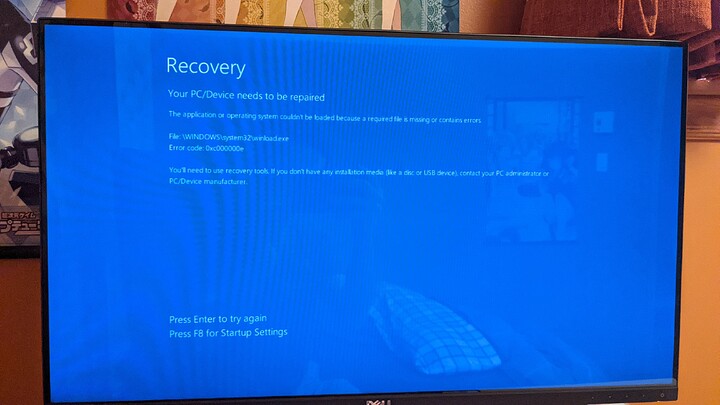

So after a swift build everything work. Well except the actual Windows partition from by previous build, Neptunia mk3  . I don’t think it liked different CPU, mobo and ram at the same time. Doesn’t want to budge from that blue screen. So just gonna go directly to Windows 11.

. I don’t think it liked different CPU, mobo and ram at the same time. Doesn’t want to budge from that blue screen. So just gonna go directly to Windows 11.

At least everything fits!

Installed Windows 11. Do enjoy it for as long as I used it. Just need to change some habits I had on Windows 10 (I always went at the lower right corner to open settings).

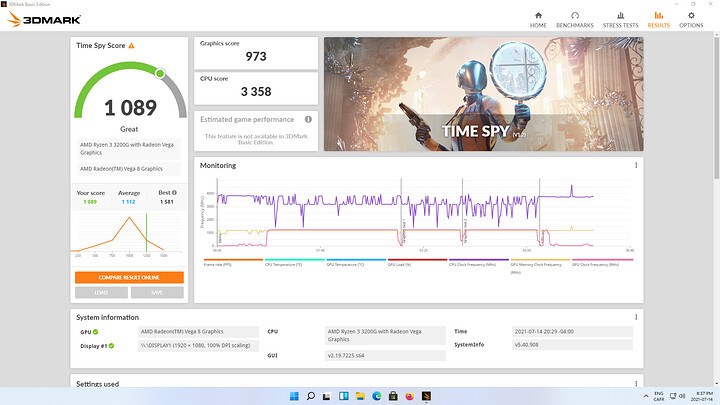

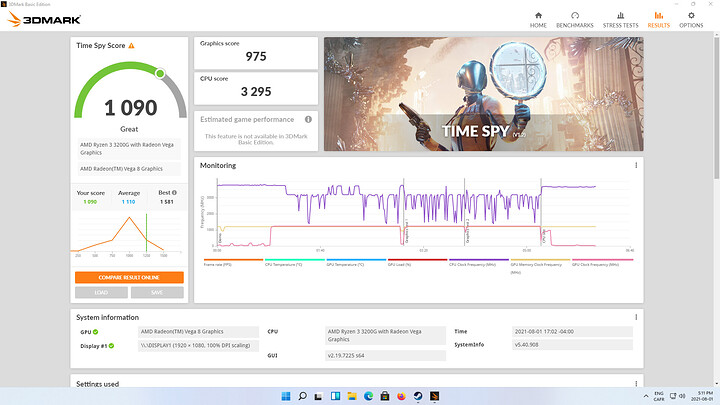

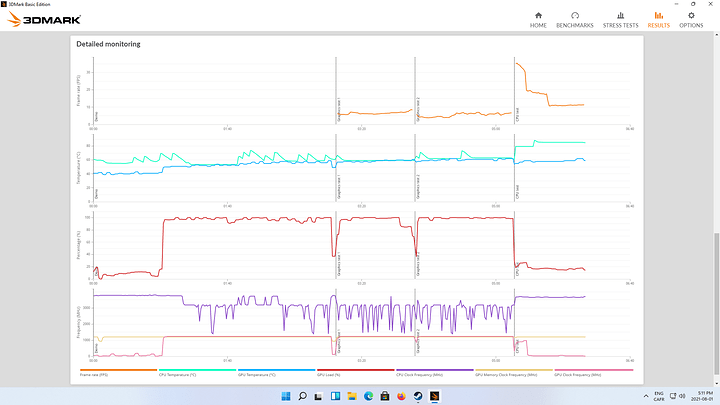

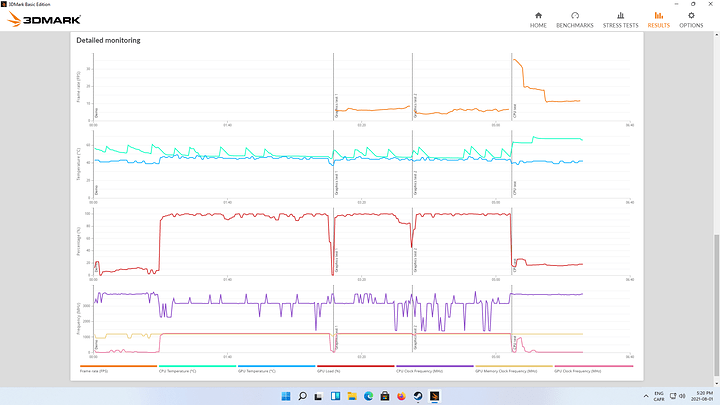

For posterity, I run Time Spy, so now I have a baseline to compare to when the project will be done.

Work on the Dreamcast shell going well. Today I sanded down the paint so I would be able to repaint, this time correctly. It took so long, but the prep will pay off (hopefully).

And I continue restoring the spirit back to the Dreamcast shell. Redid the mechanism keeping the lid close, and opening it, with two standoffs. Works beautifully.

And I’m even putting back the section that I removed that was envelopping the extension to give back strenght to this part of the frame.

Body work finished. I’m happy of having done that, brought back the Dreamcast spirit to the build.

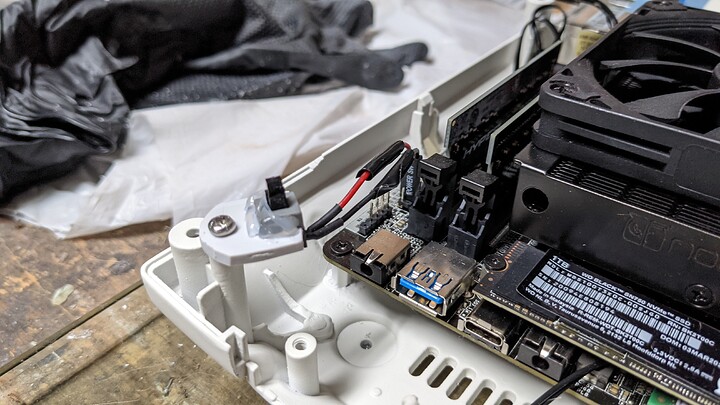

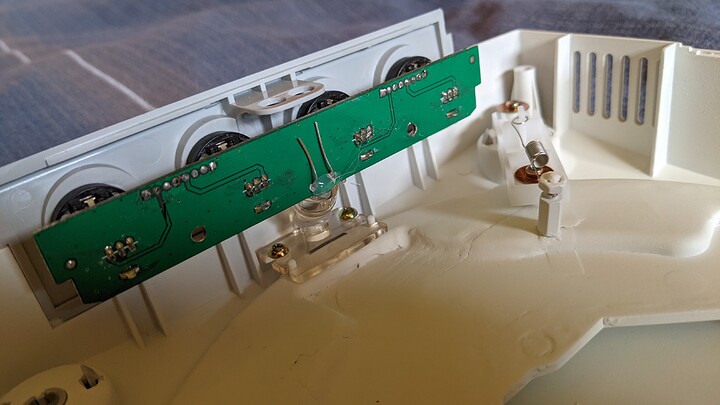

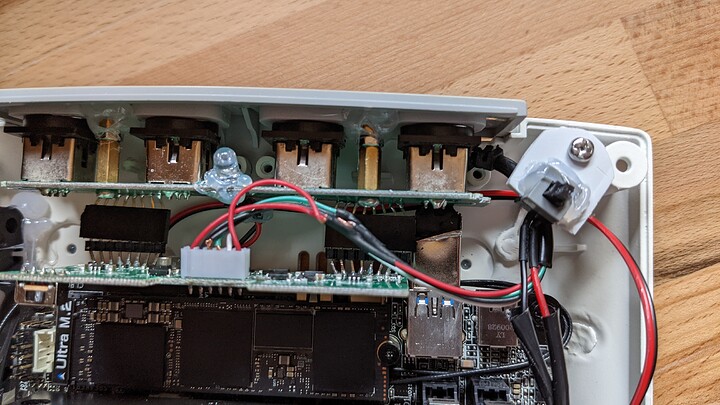

And the standoff are glued down, final position of the MOBO.

Look at that clearance

Finally, I decided I will paint matte white again, but I will be patient this time and choosing a good spray paint this time. But will have have to wait for a day that is not too humid… (might take some time).

Also I was ready to retrobright (thanks to @GigaBusterEXE for lettign me know about that) the grey parts, using the sun for it’s UVs, but it hided itself behind the clouds the whole afternoon…

Did the retrobright. After 2 hours, the result is good. There is still a light hint of yellow on the controller faceplate, but that is surely because it was hot today, increasing the rate by which the peroxide broke down in water and O2, and making it less effective.

Before and after:

Before and after:

Was able to do a first coat of paint today of white. Will do a clear coat not before two days, but anyway next week will be pretty much rainy so I hope I would be able to do the clear coat next week-end.

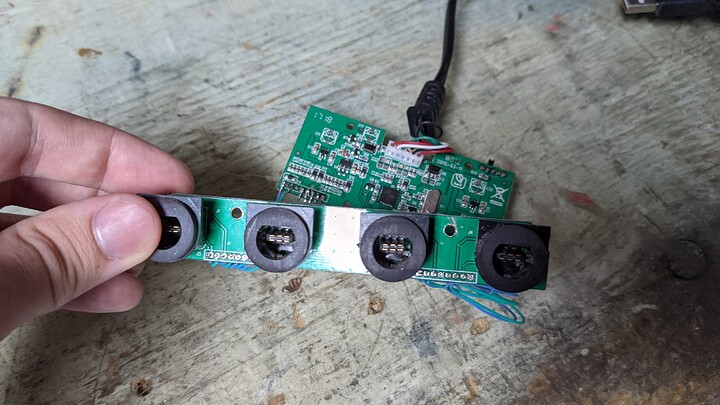

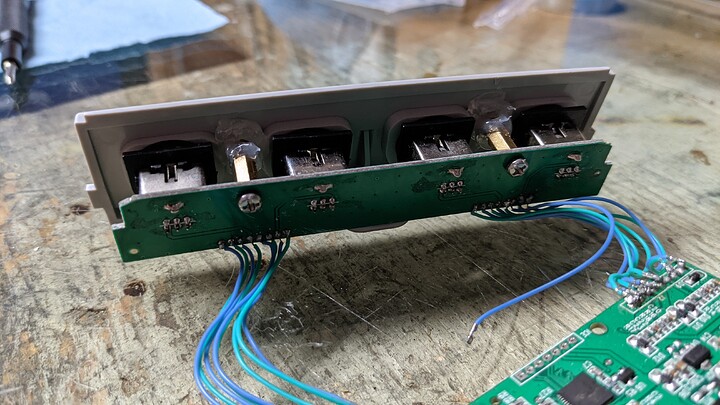

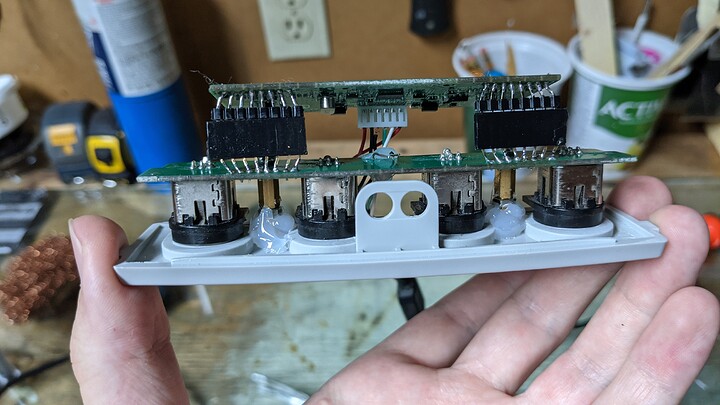

Also began to work on mounting the connector board to the connector plate. Hit glued standoff and drilled the PCB to screw it down, so I can easily remove it if needed. Will use pin headers to connect the logic board with the controller board to have something compact.

Progressed a little bit with the build. Done the clear coat yesterday. And now there is still a slight yellow hue, so it’s clear coat that do that. Note to myself, never paint a project primarily white next time.

Also, a little lack of insight, but had to sand down a little bit the button holes so the buttons could move freely. Thought about that, but didn’t not put tape prior to painting.

Speaking of tight clearances, well now the extension piece is stuck with the bottom piece. Wanted to test fit, had to jam it a little it, and now I’m unable to remove it. But not a big deal, just gonna jam at some point an antenna inside by the hole. And the little pieces have been added back.

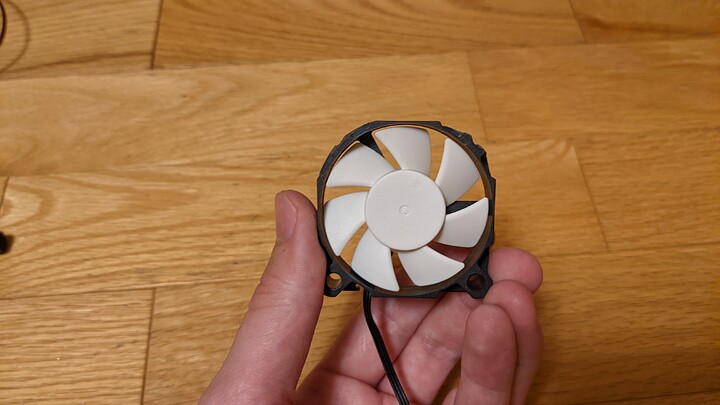

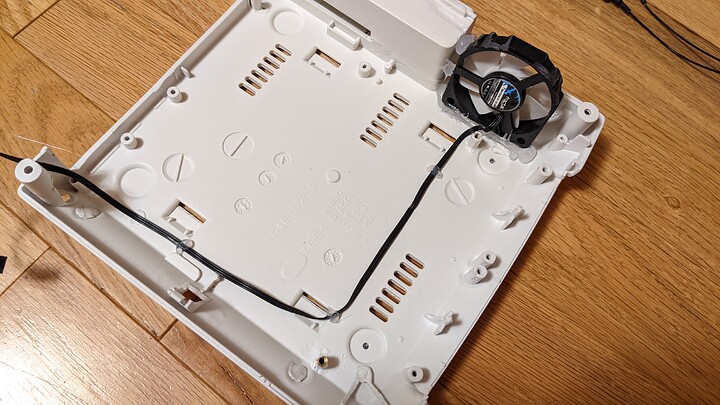

And installed the intake fan. Had the 50mm fractal fan, didn’t want to buy a 40mm one, and realized I didn’t need the mounting holes, so I removed them. And then trusty hot glue to install the fan and manage its cable.

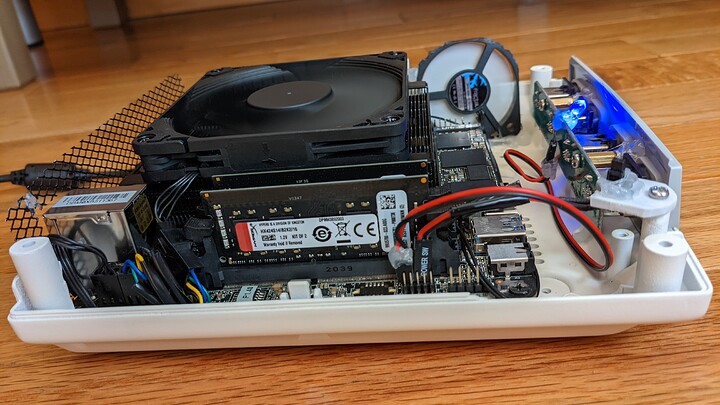

Uzume is partially completed! So I made big strides in the project, because I was eager to have it assembled. Had ideas of how to do different things that I like that I come up with as it made the build more thoughtful and less “hot glue everywhere”.

First, I use the original screwing hole to mount the power button in the Dreamcast, for, well, mounting at the same location a power button. Use a leftover plastic piece to carve out a retaining piece for the power button. Could have left like that, but I also added some hot glue to make sure everything is secured. Also, fill the inside of the plastic shell of the power button to make sure the switch can push back adequately after it’s pressed down.

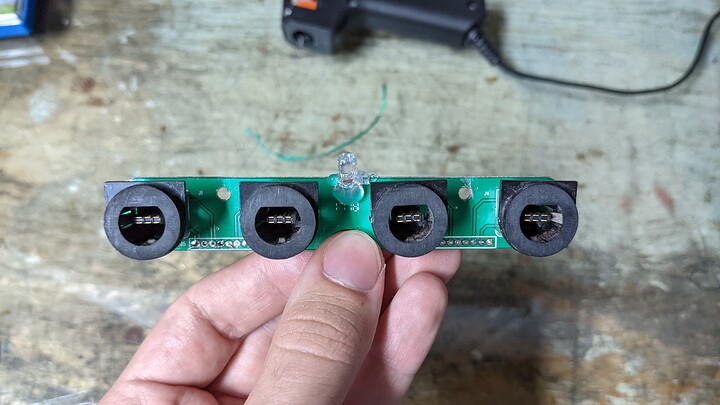

Second, I shorten the light diffuser assemble so it would fit even with the controller port board in the way. Made two small holes in the pcb of the controller port board to install the led. The led sit flush with the light diffuser when the top part is installed.

I forgot to take a picture of it, but because the extension part is stuck with the bottom piece, and as there is one of the screws that requires the extension to be removed to screwed in/out, I drilled an hole in order to have access to that hole and be able to screw all 4 posts.

Also, did a small extension for the the CPU fan, and mounted the back “plate” io (aka cutted metal mesh), and used an unused wifi antenna to glue the pcb part inside the extension hole.

Everything mounted down and working.

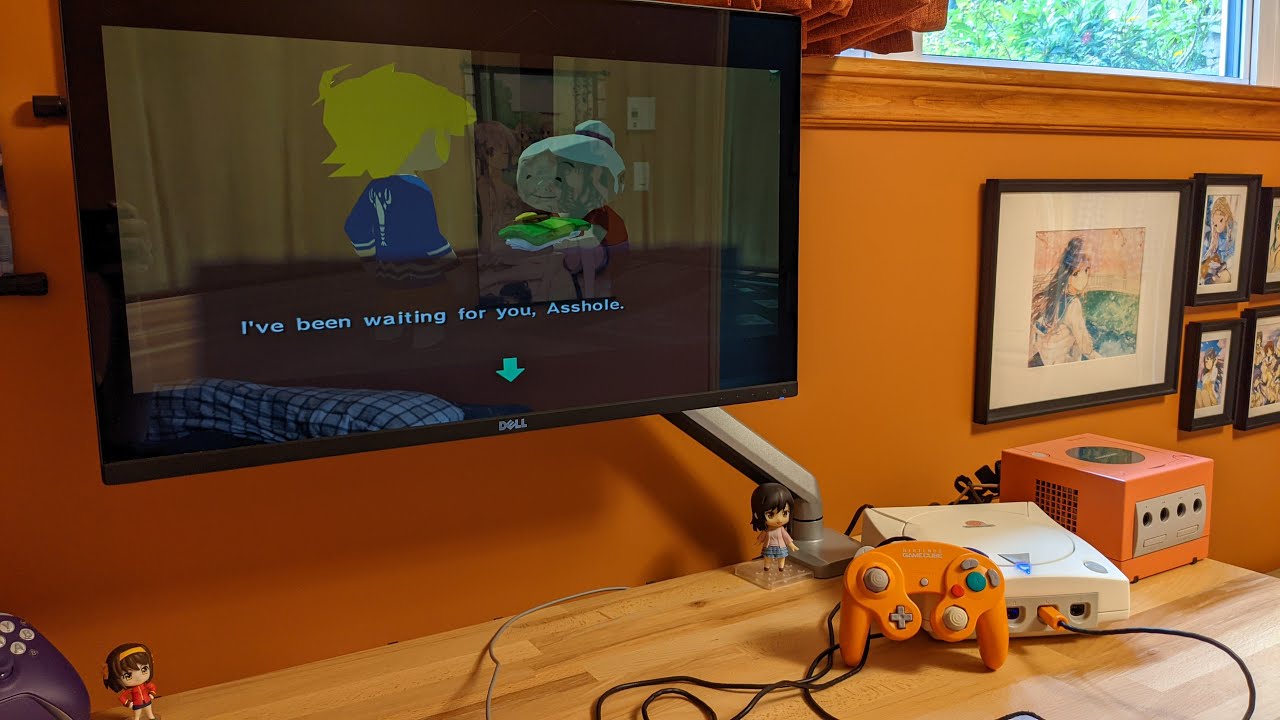

And fully assembled and working fabulously.

There is only work to be done in order to make the controller ports functional. I intend to solder headers to the controller port board and the pins to the logic board so I can neatly assemble it compact. But I need to acquire a proper iron, and I don’t feel like being frustrated soldering, so that will wait a little bit.

Also, I’m waiting for a sticker for the front logo.

Performance wise, there is no difference really between the open air system and inside the shell either with lid close or open. Same 1089 score on Time Spy.

Lid close:

Lid open (I forgot to screenshot the score, but it 1089) :

It looks fabulous! Awesome job.

The controller ports work!*

*(Well only the 3rd and 4th because I damaged traces last weekend, would need to buy a new one)

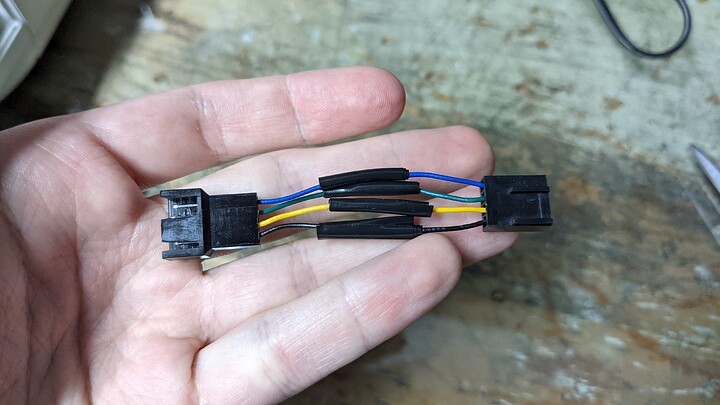

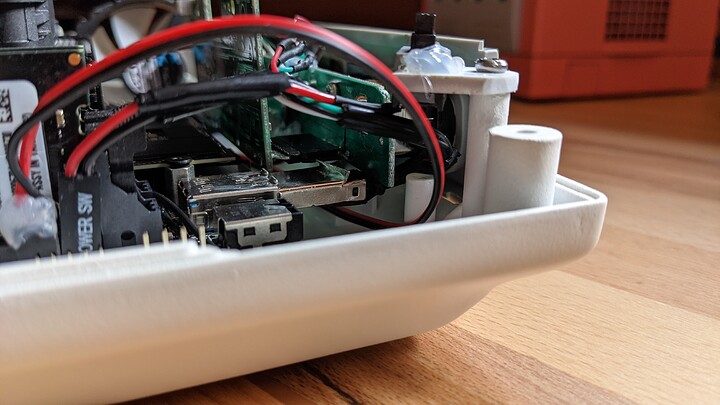

Despite not having the appropriate pin headers (had on hands some with a 2.5mm pitch, but none with a 2mm pitch) I still went ahead and solder everything together. It works (when the adapter is recognized as a Mayflash one, and not as a pokken controller …) and suprisingly everything fit inside.

Sure if I do any commission (I hope I will have some) I will obviously use 2mm pitch pin headers, and properly mounted through the holes. But as I kinda abused that particular adapter and botched a previous repair on them, I was not able to remove solder in the holes. Maybe I will contact Mayflash to have the boards, but without any wires soldered.

Had to remove all the sheathing on the usb plug to make it fit. Next time I will just get a usb header to solder instead.

Played Wind Waker on a Dreamcast  And did a little wink to the original inspiration

And did a little wink to the original inspiration

I will post the sexy pictures when I will received stickers of Uzume logo to put in the front for the final touch.

Out of boredom, I’m now beginning to thinker with the idea to power the Gamecube with USB C cables. Not sure if that idea will fleshed out with my current PC, or if it will happen in an eventual Gamecube v2. Anyway, I’m beginning the thought process here as it will eventually involved new learnings, such as step-down conversion and PCB making.

“PCB making? What are you saying?” Hold with me here. First, my idea is to use one of those few 200W USB C GaN charger with two ports providing up to 100W (or maybe just two 100W GaN chargers) to provide up to 100W to the PN50, and to the GPU, independently.

If you follow a little bit the news around USB standards, you might wander why I don’t wait for the USB PD Revision 3.1 to land, which would allow up to 240W with a single cable. Although it will be an interesting idea, the spec would be able to obtain those wattage with the use of voltages up to 48V. This would require me afterward to step down the current twice, one time to 19V for the PN50, and one time to 12V for the GPU, which might be space consuming to do.

Therefore, the idea is to use two USB C cables, and to use those nifty USB PD handshake module to ask for 20V charging. However, ideally I would like not risking to solder something on the PN50, so using instead a PN51-S1 (or a future PN52S) which accepts power delivery on the rear USB C is an idea I’m considering.

Staying on 12V as of right now is not the best experience on the long term, as 12V power bricks are rare (and bulky), and powering the PN50 with 12V do bring a performance hit, although it doesn’t really affect me in my use.

“Ok but what does PCB making has to do with all that?” Here’s the fun part. It’s part of a greater idea to make a tighter, more professional Gamecube PC with an eventual v2. With the USB C power delivery, I will be dealing with 20V. No problem for the PN51 as it deals usually with 19V and feeding it 20V will probably be a non-issue.

However, I need to step-down the “up to” 20V 5A down to 12V 8A for the GPU (I’m keeping my option open to power a 90W TDP GPU, like maybe an eventual 3050?). I cannot ask the USB PD module to ask that kind of current, as USB PD specs cap out the 12V delivery at 3A. Plus, I need to use a something like the GxR-DIY to switch the power on or off depending of the power state of the PN50.

With those limitations and consideration, I’m actually tinkering about designing a PCB to have a tidy power delivery thingy for the GPU.

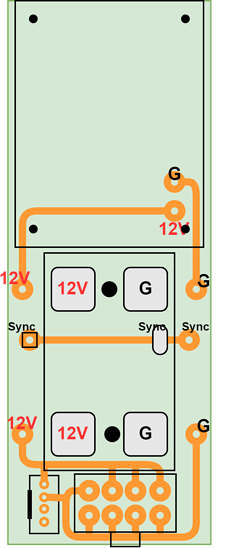

I would solder to it a 12V, 15A Step-Down Voltage Regulator to step down the 20V to a 12V, and I would solder the GxR-DIY to it for the power switch. Plus I would put on the PCB a 8 in GPU socket to power any eventual GPUs, and a 4 pins molex header to power the NVME to PCIE riser. Also, it would have the pin on it to sync with the PN50. The traces on the PCB would be 5mm wide to be sure they can deal with a current up to 8A, judging by this table.

It would be so tidy and professional looking. ^^ I still need to look how I could optimize and reduce the size of the PCB. And if I put inside my current Gamecube, it would require some additional chopping off of plastic so it can fits. So that’s what boredom is trowing me into right now. Beginning to think about it, but might be a while before I put it into execution.

Dumb question but could you not simply do the 230W, do a voltage split with two resistors, then parallell buck instead of two step Buck?

I only know enough EE to be dangerous here.

Maybe, I don’t know, but space for two buck converter would still be a challenge. Plus at least with two cables, I can only power the PN50 and run off the integrated GPU if needed.

I only know enough EE to be dangerous here.

Same here

This would require me afterward to step down the current twice, one time to 19V for the PN50, and one time to 12V for the GPU, which might be space consuming to do.

19V will be a pain since that is such a non-standard voltage.

Then again, when you go custom-PCB, creating your own DC-DC setup is not a big step anymore.

I would solder to it a 12V, 15A Step-Down Voltage Regulator to step down the 20V to a 12V

I had good luck with Traco Power products for projects that needed small (<5W) DC-DC conversion, they make bigger units too. Just to open up your options.

I only know enough EE to be dangerous here.

Makes us 3, then again, my last fire was two years ago.