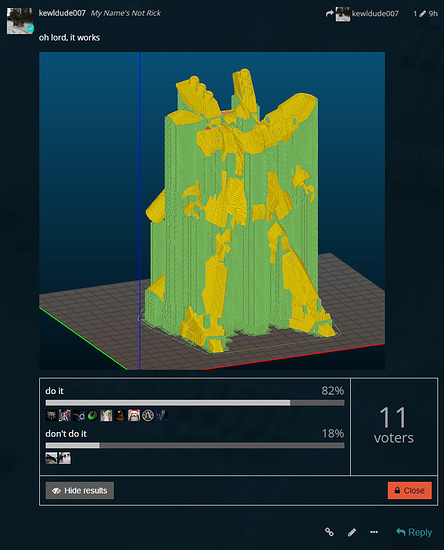

That is one of those terms when every time I see it I have to consult Urban Dictionary.

What is praise Kek?

Kuk (also spelled as Kek or Keku) is the deification of the primordial concept of darkness in ancient Egyptian religion… …Like all four dualistic concepts in the Ogdoad, Kuk's male form was depicted as a frog, or as a frog-headed man, and the female form as a snake, or a snake-headed woman.

Now I'm even more confused. I think I will stay blissfully unaware.

@kewldude007 Being the 3D printing noob I am, I was wondering if this extruder is compatible with the Prusa mk2?

About to pull the trigger on a Prusa and an enclosure, but waiting to get some prints under my belt before upgrading to this extruder.

Any reason you would do this? The stock one works very well

Also search Titan aero

To print with polycarb for HPA/CO2 applications.

Should I buy the Anet A8 for myself as a cheap starter printer.

This is the same question I asked (even started a thread for it). Its basically a lower quality Prusa, so upgrades will be necessary, like replacing the mosfet and using it to print upgrades and add-ons for itself lol

Holy shit, the Prusa has a lead time of 7 weeks.....

standard prusa can print PC

you can

understatement

yep

Vader’s patent pending MagnetoJet technology is based on the study of Magneto Hydro Dynamics (MHD), or more simply: the manipulation of liquid metal through magnetism. MagnetoJet’s extraordinary physics are accomplished by depositing Aluminum wire into an 1200°C ceramic chamber, where it is influenced into a molten state. This molten media is then electromagnetically pulsed – causing a droplet to form and eject with precision from a carefully crafted ceramic nozzle.

The Zmorph 2.0 sounds like a beast.

Because it’s not just a 3D printer; it’s also a CNC router and laser cutter.

Next level.

It's pretty damn fast for what it does.

720HP

1300 Lb

3D printed car

The car itself is beautiful but the engineering and manufacture is a masterpiece. So smart and cost effective too. What they try to do is print connectors from optimized materials and then use standard carbon fiber or aluminum tubes, etc. to save time and money.

Look at those A?-arms. They did not design them to appear to be organic like the internal structure of bones. The Divergent engineers fed parameters into a computer algorithm and the program determined the most efficient form. It just happens to look like God did it.

Well my Creality cr-10 came in. As of tomorrow I would have it for a week, and I have a few things to say about it. Keep in mind before I got this printer I had zero experience, with one, only a little web browsing research.

1. I had this thing put together in 10 minutes, it even came with a few spare parts. It was mostly together.

2. Once I got the base levelled, and aligned with the printer head, I used the paper trick for that, the first thing I printed was the filament guide. At .2mm I thought it was perfect, until I started to print at .1mm. WOW what a nice job. It made a near perfect ball.

3. Glass came with masking tape already on it, as well as a roll of extra tape... which of course I needed. I had a coupe of issues printing a coule things... warping was the biggest problem, then I read somewhere that a bed with glass requires 70 not 60 degrees.

4. I printed a vernier calipers as one piece, however I didnt slide , as the gaps were a little tight, perhaps wrong scale, and definately wrong print size. This is when I discovered .1mm layers.

5. The learning curve to use this machine, as it is the first one I have ever used was pretty easy. It took me no time to figure things out.

6. It came with sd card and usb adapter, with decent instructions, if you require them, as well as all the tools to take it apart.

7. I succesfully made a hinged filament filter (single piece), which worked great. Since there are a couple dogs and plenty of dust to go around in my neck of the world, i figured an ounce of prevention is better then a pound of cure.

8. It has a HUGE footprint, and doesnt take up a lot more space then the footprint, mine takes up half a coffe table, until I get one made for it.

9. Best 650$ Canadian I have spent in a long time. What a good deal, that included shipping duty, and whatever else came along with it. Thanks @Mora for the suggestion of this printer.

It looks like the calipers are done...