Coming along quickly it seems

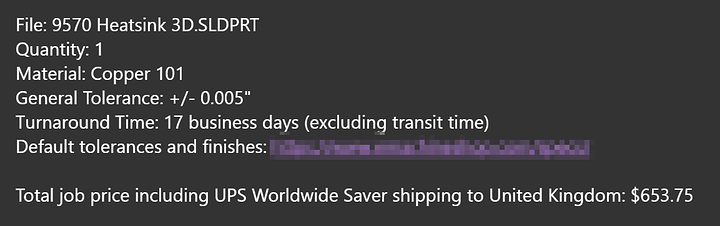

Thought I’d see how ridiculous online companies would be. We have a winner.

Also advertised as a UK company, but’s actually in the US.

One of my mates might be able to CNC the block for me at his work. I will owe many pints.

I’ve sent them the drawings, and they’re going to try and do it in aluminium first, before using my copper.

I see, alcoholic beverages are also accepted currency for craftsmen on the Isles.

lifts glass

cheers!

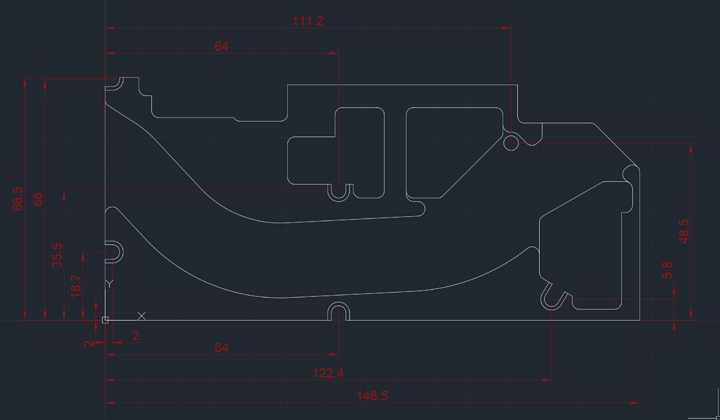

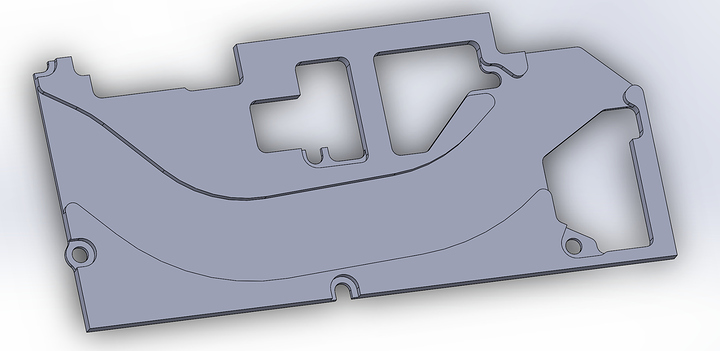

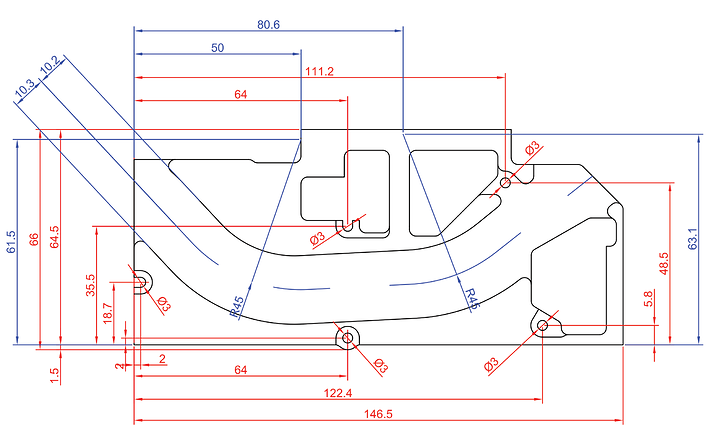

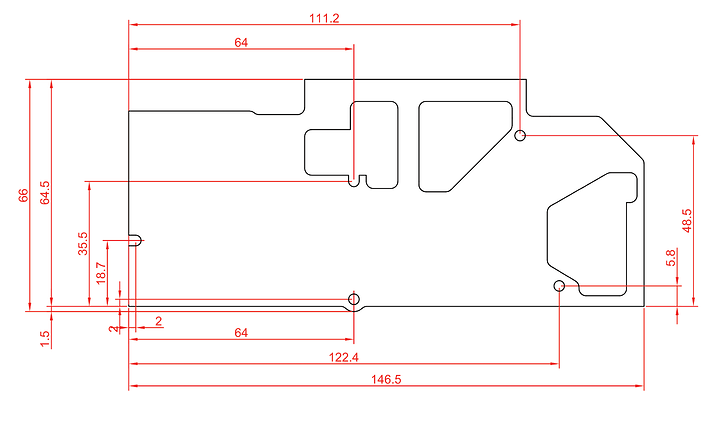

Right. I can get it CNC’d at my mate’s work, but they don’t have a 3mm bit. To get around this, I’ve widened the holes to 4mm diameter, and I’ve ordered some M2.5 x 4mm outer diameter nylon bushing. The plan is to cut the bushing to the thickness of the copper (and take a bit off the diameter), and sandwich it between two washers, one either side of the block. As this will rely on my measurements of the mounting holes being spot on, failing this, I could sandwich the spring that I have instead (OD 3.15mm), which give a bit more wiggle room.

Edit: Also taken off the top right corner, which wasn’t covering any components. Going to play with the holes and slots to strengthen them up a bit.

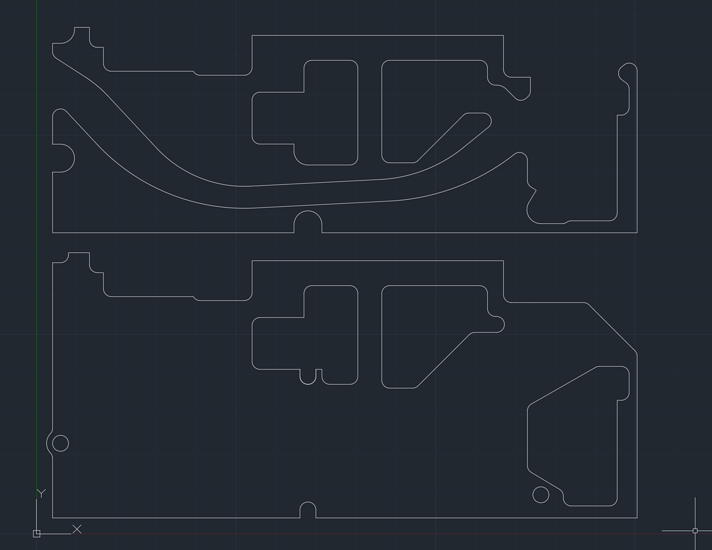

Edit 2: What I’m hoping is the final design.

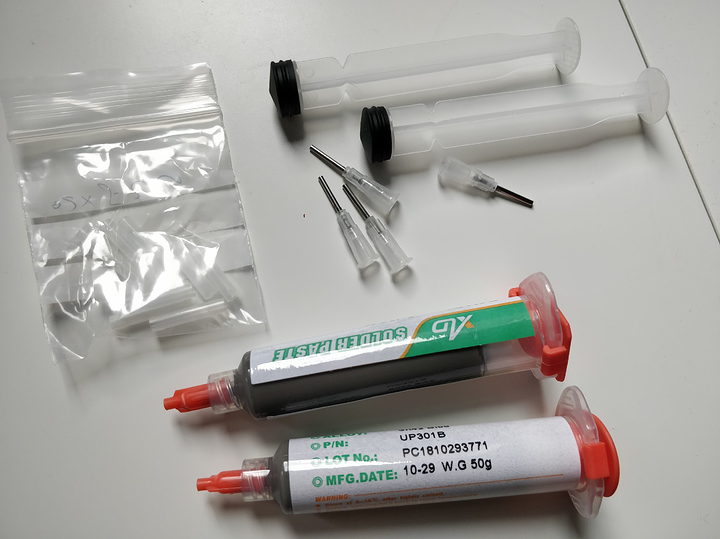

Solder paste and washers turned up. Just waiting on my mate now for the prototype version. Has to do it in his lunch breaks, so I’m not rushing him.

Been distracted for the last couple of weeks, and just looking at this again.

My mate’s been stacked out at work, and it doesn’t look like it’ll happen any time soon, so I’ve decided to get some quotes to have it laser cut from 1.5mm copper instead, and then stack the parts together. Would just mean putting a little jig together for soldering, but would be massively less expensive than paying for milling.

I’ve asked for a quotes for just the outline (bottom part of the drawing) in 1.5mm aluminium, so I can test screw locations and how far it sits off components, and get shims made, if necessary. The CPU and GPU sitting at different heights is the only place this’ll matter, because the SMDs can just be packed with different sizes pads.

Still looking around for the best price I can get. Sent off for another few quotes today, both CNC’d and laser cut. The chronically underdimensioned drawings go down surprisingly well. Laser cutting from 1.5mm copper, and not bothering with the top bits costs about £35. If I also get the top bits, it’s £65.

CNCing is a bit dearer, but I’m willing to pay for the extra sturdiness. To save on CNC costs, I’ve ordered 20x20mm 0.5mm and 0.8mm shims. Putting a shim above the CPU is easier than taking material off above the GPU.

I have access to a small 3 axis CNC mill. (and an 9570)

If you want to send me a STEP file, I could try it out.

Thanks. So the shop is extremely busy right now, so it might be a bit before we can sneak it in. (and get the stock) but I’d be happy to try it.

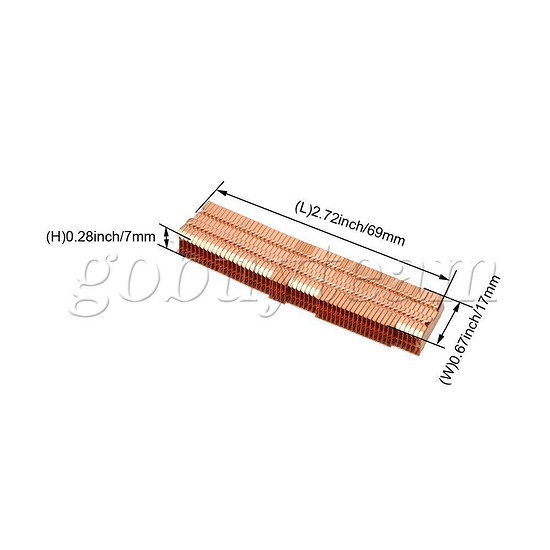

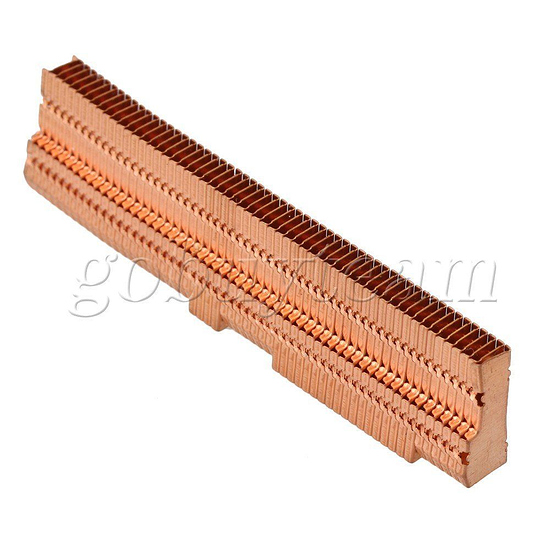

Had a double check on clearances. Going to order the above design in 1mm (just in case), and I’ve also just ordered a couple of these fin stacks. Same 69mm width as the originals, 2mm taller (means we might need some polyamide tape to stop heat transfer to the keyboard/bottom panel, as we can’t fit the old pads), and 2mm less depth. Copper fins means they can be soldered to the heatpipes, increasing rate the fans can dissipate the heat compared to the aluminium which is attached with thermal adhesive.

Reddit user u/asaggynoodle made a good video showing how hot the VRMs during load of CPU and both the CPU and GPU. Looks to me like the chokes are heated more by mosfets via the PCB than by their own operation, so hopefully dealing with the mosfet heat will mean the chokes stay relatively cool.

Waiting on everything to arrive now. Also ordered these screws, which could make mounting far less of a hassle. (anyone want to buy 25 M2x6.8mm spring screws, unused haha)

The fin stacks I ordered from eBay are also coming from China, so it’ll probably be a week or two before they arrive.

Good post on NotebookReview forums of a user showing off a custom XPS 15 heatsink they got from Chinese website TaoBao, which has two sets of heatipipes stacked. Considering that fits with minimal problems, if I get bad heat buildup on the plate I’ve designed, I’ll get a 1x9mm heatpipe to run from fin stack to fin stack, over the VRM area.

After this project is done, maybe switch out the plastic casing for a custom metal one.

Turns entire laptop into heatsink

For all intents and purposes, the plastic on this thing is very sturdy.

looked into shapeways? Could have the part 3d printed in steel or aluminium.

Already ordered it earlier this week. 3D printing metal is still much more expensive than any subtractive process right now. Better for more detailed things. Looking at double or triple the price for printing this.

There are a few companies in the UK that can print in copper, but most of the companies I found are using a zirconium chromium copper alloy, which is less conductive than pure copper (pretty negligibly, but still). Either that, or they’re printing a wax model and just investment casting the part, which would produce much worse ‘flat’ surfaces.

I believe that is what shapeways ends up doing too. At least for the like of the jewelry they show off.