BRIEF:

I have an IC with 1.27mm ish pitch, 8 pins total, 4 pins either side. In tech speak that’s S08 SOIC.

I want to adapt/attach into a DIP form factor > then back into a standard SMT form factor to go onto a board.

Essentially: IC > IC / DIP ADAPTER > DIP / IC ADAPTER > SMT connection

This creates a DIP area between the IC and the BOARD’s SMT mounting contacts.

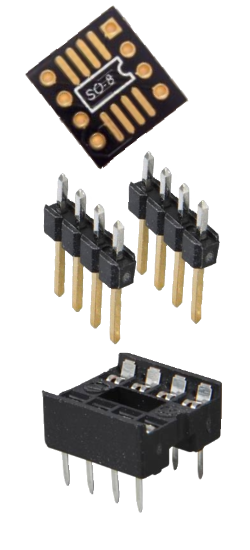

SO8 IC/DIP Adapters:

IC converted to DIP adapter01-aa

https://www.ebay.com/itm/162316391625

DIP converted back to SMT adapter02-aa (url says “adaptor”.  sad!)

sad!)

https://www.westfloridacomponents.com/S036PD/8+Pin+Dip+to+8+Pin+Surface+Mount+IC+Adaptor+1-348466-5.html

The Questions:

⁞

⁞

This IC to DIP adapter adapter01-aa is what I will place my small SOIC chip onto.

Q1: How will the DIP “rods” (posts) mount through the circular contacts on either side with this adapter? It appears to me that the holes have solid material in the way… Perhaps this requires a special post that attaches to the board without penetrating it like a normal DIP post does?

- See related listings below the main item which have holes through the board for standard DIP mounting

- It is possible because the seller has used soft lighting, the color of the gold contacts surrounding the “hole” are reflecting gold light onto the white surface beneath the adapter, making it appear solid gold to an untrained eye.

⁞

⁞

This DIP to SMT adapter adapter02-aa is what my newly named "DIPCHIP" ;-) will mount to. The SMT part will go onto a board. I was hoping to make my life easy and lazy by removing the need to solder my DIPCHIP when taking my DIPCHIP from board to board.

Q2: Do you think the DIP Pin connection will be good enough to be SOLDERLESS?

- This adapter obviously is solderless, but I feel the need to ask whether a solderless adapter is appropriate for my use.

- The chip will be part of an “at home production environment” which basically means downtime and breakage is bad, but not absolutely catastrophic. I don’t expect 100% reliability, but am hoping for something that works nearly always, and will get used a lot.

Thanks for your time, I look forward to discussion.

On a sidenote, I would really appreciate being allowed to use white space to pad text. I’ve wasted time formatting this document to allow for readability despite the limitations, however it would be nice to use more than a single space in certain instances.

I have other recommendations also but I should probably save this for a separate post elsewhere.

unimportant garbage: There’s a lot of garbage talk about DIPCHIPS and random crap like that. I wrote that to help me write and was going to swap it out but y’know it’s easier just to make excuses for not cleaning up the post down here, so here I make excuses. Sorry for not making sense.