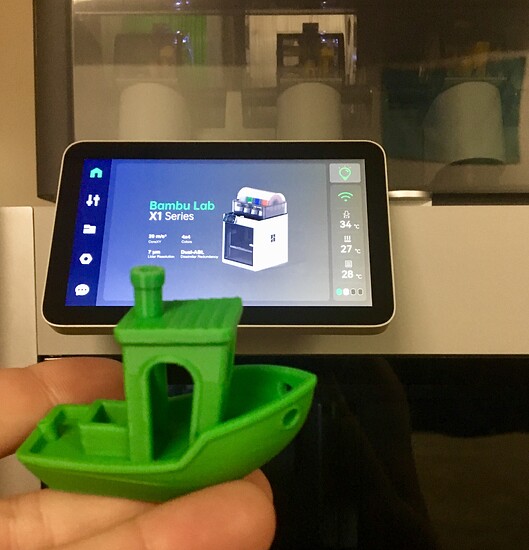

I think I know what I want my second printer to be, an X1 Carbon with the AMS system. We may never financially recover from this one lmao

Yeah, as much time, effort, and money I have spent on making my Ender 3 V2 what it is now I would have rather bought a Bambu. They weren’t available at the time tbf.

Any fellow Bambu owners in the chat?

Yesterday I unboxed my X1 Carbon and it’s everything people say it is and more.

The P1 is just as fast and also works with the auto-feed system, but keep in mind the sunk cost fallacy of future upgrades when choosing between the two. I will still recommend the Ender 3 to anyone with a budget under $300, especially the factory upgraded models, but if you have the funds a Bambu is well worth the investment in time saved alone.

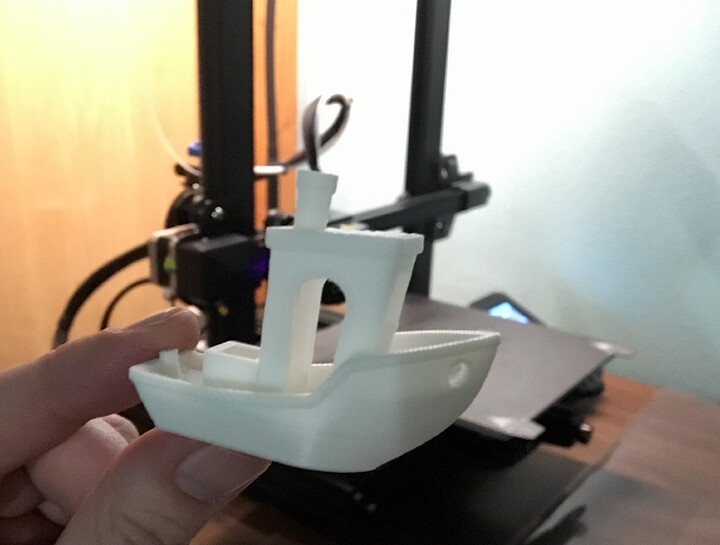

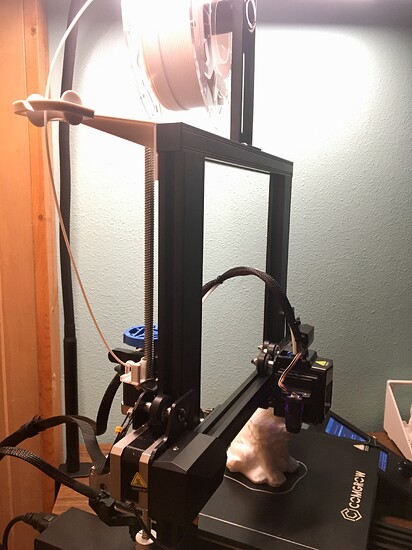

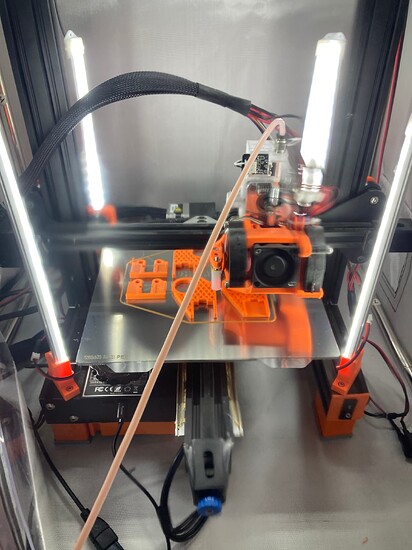

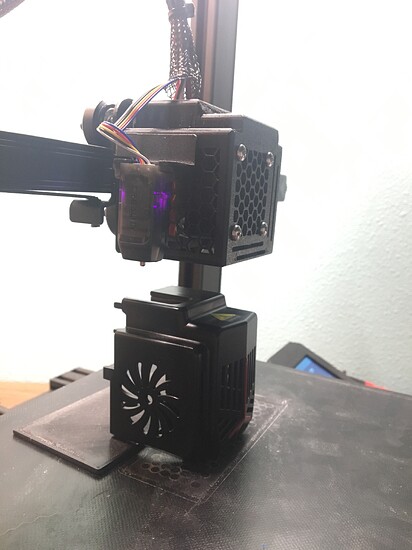

My Ender 3 V2 Neo with printed filament guide and LCD cover. I would still like to at least upgrade the heatsink fan with a quieter 4020 mag-lev.

I think the two best things I did for my Ender was the dual Z belt mod and the BL Touch. Between the two I think that is like $70 or so of hardware. Cooling ducts were important and I also hardmounted the bed. Got rid of the springs and just ran a nut up to the bottom of the bed then another nut on top of the carriage.

I bought a G10 (Garolite, FR4) sheet from AliExpress. I saw a couple of clips about it on youtube. Supposedly things stick really well to it, and PETG don’t stick too well. A bit hard but worst case I have some handymen working on the house who might have a plasma cutter or something ![]()

Innnnnteresting. That first thumbnail has a very nineties-comic book-shading look to it too.

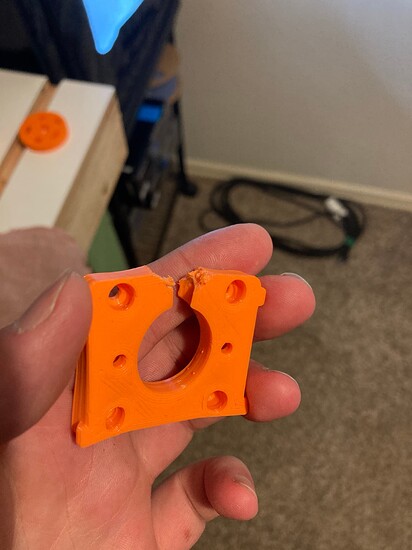

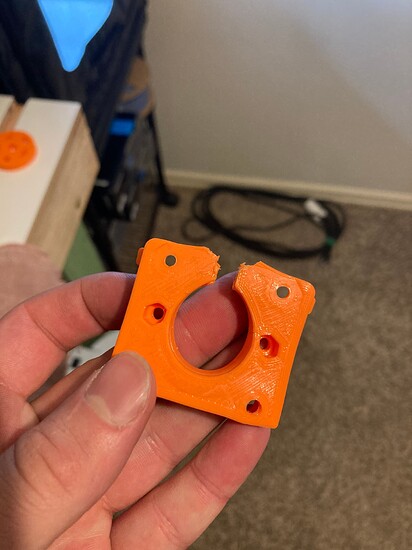

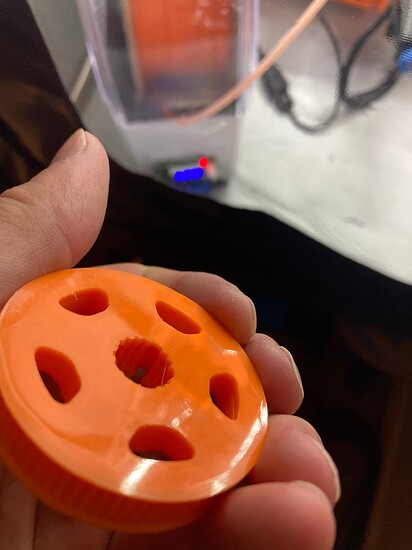

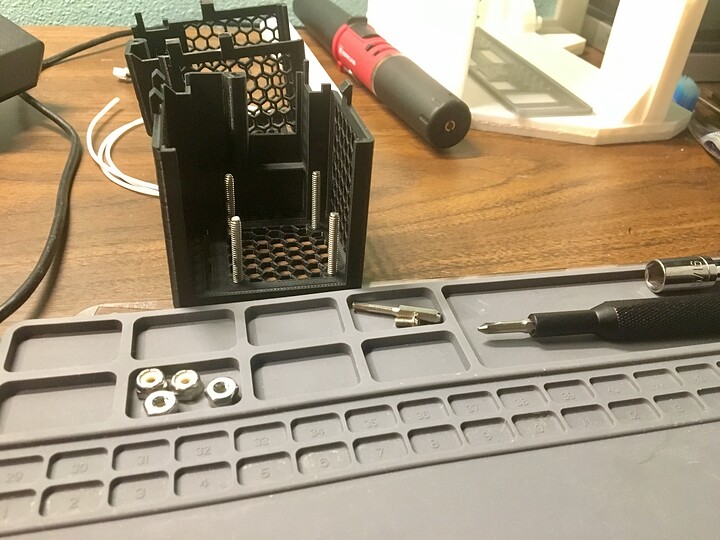

Some parts that I printed for my dual-z upgrade have started to fail. I printed them out of PLA+ originally and the instructions called for ABS or Nylon so I am not really surprised. The part here is the mounting plate for the Z motor. The area that is busted is where the tension bolt was located. I replaced it with ABS and am now re-printing some of the other parts as well.

The new gear and pulley mounts.

How did the G10 work out? I have been super happy with my WhamBam PEX surface but I ruined one sheet already printing PETG and it fuzed to to the build plate. Was thinking about getting a dedicated build plate for TPU and PETG because they stick too well in most cases.

I don’t remember who suggested it but I did change my 120v heated bed relay to cycle at 30Hz so that my lights don’t flicker nearly as badly as they did before. If I am looking for it I can still see a faint flicker but if I am actively paying attention to something else it isn’t noticeable. Def not inducing headaches like before.

Oh, I just changed lightbulbs. Different LED bulbs that weren’t susceptible, but that works too!

I just spent a bunch of money for WRGB smart bulbs so I was inclined to try the software fix first.

Ugh, so the thermistor in my bed died. Checked the wiring harness and there aren’t any breaks. Mainboard plug is good. Swapped the hotend and the bed plugs and the problem followed the bed. I will have to do some surgery since the bed is a silicone mat style heater.

Very good. I don’t really understand how it can both stick good and be so easy to pick it off. Even PETG is easy to get off.

Not that easy to cut up though.

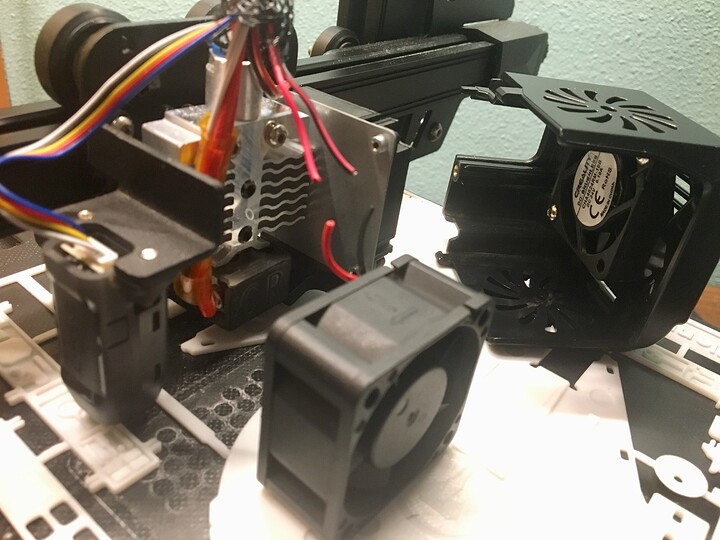

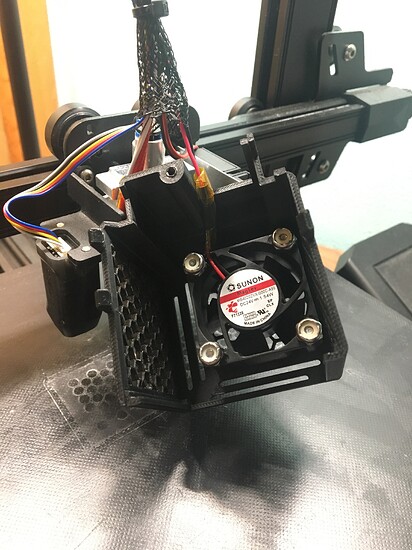

I replaced the 4010 extruder fan with a 4020 mag-lev on my Ender 3. Too bad it’s not any quieter being rated for 1.5w instead of 2.5w. Looks like I’m going to have to use inline resistors to drop the voltage to 20-22v to see any noise reduction.

I would highly encourage just getting a cheap enclosure. Did a lot to tame the noise on mine. Especially when I am printing PLA fast and my fans are cranked.

Just did some maintenance on mine. Greased the linear rails on the Y axis and changed out the nozzle for a hardened steel one. Somehow my brass nozzle has loosened itself and started weeping plastic out the top into the heat brake.

Good point about the enclosure, I’ll probably end up doing both.

I’d just say that if you have any structural parts on your printer that you printed for it make sure you re-print them in ABS after you get the enclosure. My dual-z axis parts I had printed in PLA+ started to stretch and warp when I started running the enclosure.

Not a big fan of ABS, but I have PETG on hand and for anything stronger with greater heat resistance there’s always PC.

That’s the “clear black” poly from Bambu @ $40/kg

Damn that prints nice. I am currently using up the last of my PETG. I really do not like how it prints. Just kinda a PITA.

It prints high temp materials great once you re-align the factory set bed ![]()