probably a 1% or 2% scale increase

Looks like defaults for Cura are as follows: layer height 0.2, infill 20%, top/bottom thickness 0.6mm.

I’ve messed with the infill mostly, but not the others. I may need to bump the top/bottom layer thickness up a bit, as I have noticed most prints appear rough or unfinished.

I’ve got OpenSCAD installed and I’ve played around with it a bit. Very foreign to me, will require much research. Same for FreeCad. I need to figure out how to adjust already made models for a… certain item. Not sure if it’s acceptable to discuss that here.

I’ll probably try the SD card holder scaled up just a smidge like @kewldude007 suggested. Got a few laying around and would like them in one place.

The ammo can organizer I was thinking of is like this:

Best to try and print one of the cat things and post pictures. You can tell a fair bit from that:

Print dimensions - Check the size and hence printing scale of each axis.

Gaps in print - Under extrusions?

Blobs in print - Over extrusion?

Delaminating / melting - Incorrect temperatures

Overhangs in the tail looks rough - Not enough cooling

Ringing on the faces - Could be too much acceleration or springiness in the X&Y travel

Top not smooth and clean - Could be infill too low, extrusion multiplier a bit low

Bottom not smooth and clean - Could be same as above and also the first layer gap too big

You mean some trays to go into an ammo tin? Would be easy enough to design. If you want a drag and drop solution, google sketchup might help? Online tool, so should work on Linux.

If you wanted to design something like that in Open Scad, prob easy to just do a big cube, and then subtract smaller cubes for the compartments…

Example OpenSCAD code:

// Basic parameters

box_width = 50.0; //Width of the box/tray overall

box_length = 100.0; //Length of the box/tray overall

box_height = 40.0; //Height of the box/tray

wall_thickness = 2.0; //thickness of the interior and exterior walls

x_compartments = 2.0; // Number of compartments width-wise

y_compartments = 5.0; // Number of compartments length-wise

//Boolean subtract on the bounding box and the array of compartments

difference() {

box();

compartments();

}

// Creates the bounding box

module box() {

color("green")

cube([box_width,box_length,box_height], center = false);

}

// Creates the internal compartments

module compartments()

{

x_size = (box_width - (x_compartments + 1) * wall_thickness) / x_compartments;

y_size = (box_length - (y_compartments + 1) * wall_thickness) / y_compartments;

for (j=[0:1:y_compartments-1])

for (i=[0:1:x_compartments-1])

compartment(x_size, wall_thickness + i * (x_size + wall_thickness),

y_size, wall_thickness + j * (y_size + wall_thickness));

}

//Function to create an internal compartment

module compartment(X_Size, X_Offset, Y_Size, Y_Offset)

{

color("red")

translate([X_Offset, Y_Offset, wall_thickness])

cube([X_Size,Y_Size,box_height],center = false);

}That’s amazing. Thank you so much for the sample code, it’s exactly what I’d like. I played with the dimensions and got it super close to probably fitting. Only thing I’d like to do is make slightly rounded corners. Found this code, but I’m not sure how to implement it properly.

You could do something like this. I added some of the functions to the end of the file, and used them instead of the built in cube function. I also had to do some tweaking to account for the increased size of the rounded boxes.

*edit. Fixed it up.

// Basic parameters

box_width = 75.0; //Width of the box/tray overall

box_length = 150.0; //Length of the box/tray overall

box_height = 20.0; //Height of the box/tray

box_radius = 4.0; // Radius of the main rounded edges

wall_thickness = 2.0; // Thickness of the interior and exterior walls

x_compartments = 5.0; // Number of compartments width-wise

y_compartments = 2.0; // Number of compartments length-wise

compartment_radius = 2.0; //Radius of the fillets on the compartments

accuracy = 50; //Faces on the round edges. Greater = smoother fillets etc.

//Boolean subtract on the bounding box and the array of compartments

difference() {

box();

compartments();

}

// Creates the bounding box

module box() {

color("green")

//cube([box_width,box_length,box_height], center = false);

minicylinder([box_width, box_length, box_height], box_radius);

//Can also use minisphere here for rounded top + bottom

}

// Creates the internal compartments

module compartments()

{

x_size = (box_width - (x_compartments + 1) * wall_thickness) / x_compartments;

y_size = (box_length - (y_compartments + 1) * wall_thickness) / y_compartments;

for (j=[0:1:y_compartments-1])

for (i=[0:1:x_compartments-1])

compartment(x_size, wall_thickness + i * (x_size + wall_thickness),

y_size, wall_thickness + j * (y_size + wall_thickness));

}

//Function to create an internal compartment

module compartment(X_Size, X_Offset, Y_Size, Y_Offset)

{

color("red")

translate([X_Offset, Y_Offset, wall_thickness])

//cube([X_Size,Y_Size,box_height],center = false);

minisphere([X_Size, Y_Size, box_height],compartment_radius);

}

module minicylinder(size, radius)

{

$fn=accuracy;

x = size[0] - radius * 2;

y = size[1] - radius * 2;

z = size[2];

height = z / 10; //Need to set height of cylinder, and subtract from cube height

translate([radius,radius,0])

minkowski()

{

cube(size = [x,y,z-height], center=false);

cylinder(r = radius, h=height, center=false);

}

}

//Longish render time.

module minisphere(size, radius)

{

$fn=accuracy;

x = size[0] - radius * 2;

y = size[1] - radius * 2;

z = size[2] - radius * 2;

translate([radius,radius,radius])

minkowski()

{

cube(size = [x,y,z], center=false);

sphere(r = radius, center=false);

}

}Hey, so I’m trying to print some of these:

The download link in the video description is dead, so I contacted the guy directly through email and he sent me the two stl files. Super cool dude. If anyone wants them I can post them here or something.

Anyway, I loaded them in Cura and it auto-scaled to 10,000%. I fiddled with trying to correct this, but haven’t got it quite right. I measured the original one that came with the brass catcher and copied that in Cura, but I just printed one and it doesn’t fit on an AR upper rail. Too wide.

What would cause Cura to scale like that? How can I load the stl files correctly?

No.

Lets see if I get banned for Necro’ing the 3d Printer thread. Anyone printing or designing anything fun?

I been playing with klipper for a change.

The idea here is you put a small program on the 8bit arduino and backend all the math and stuff on the raspberry pi (in python albiet) which is also running Octoprint. It typically allows for much greater printing speed and quality, if your hardware can handle it. Mine cant it seems.

Y axis (moving the bed) tends to skip, so I’m gonna have to re-do the bearings, see if I can free it up. If it is just the inertia, maybe add another stepper.

Extruder is not going well either, have an E3d titan on the way. Hope it can force the plastic through the E3d nozzle a bit faster. If not, heat-break issues, might need to redesign the mount.

Overall klipper has been pretty easy to install and get running. It comes with everything to build the remote program and flash the arduino. You need to putty in and edit one config file, but you can do quite a bit with custom g-code commands.

The rule is 6 months and I’m not gonna lock a general discussion lol

Cool! It’s also your thread!

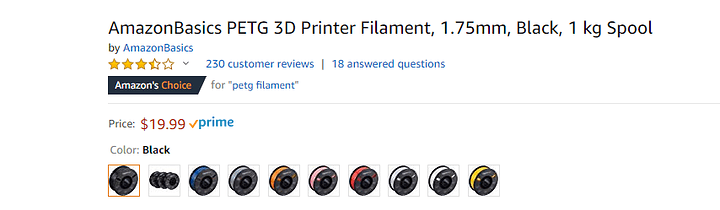

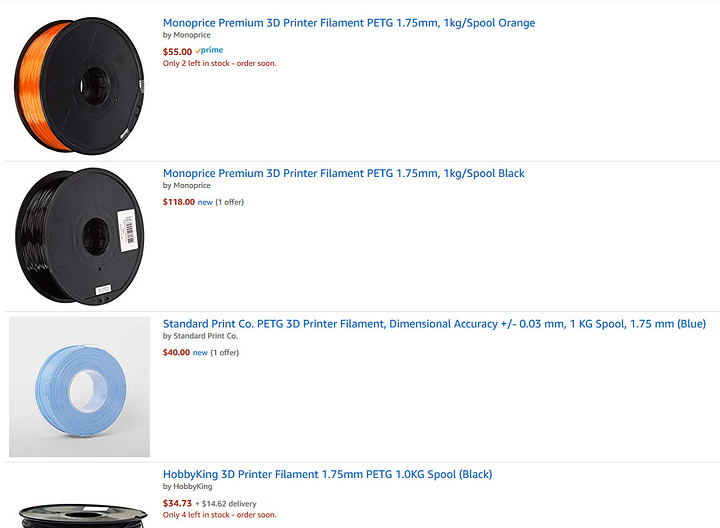

That’s affordable af

ouch.

Yeah, don’t get filament from amazon here. Not yet anyway.

I had issues with some PLA pro style filaments I was getting. It seemed harder to extrude, and prints would always end up an under-extruded mess for a while.

Turns out the silent motor steppers were stealth chopping, or not holding the current on the steppers when not stepping, so they would skip backwards fairly easy. Also there was some slip in the extruder. A billion dollars later, rocking a E3d Titan Extruder, and properly configured stepper driver, problem seems to be solved. It was fairly cheap filament also.

So what you been printing lately? Any more squirrel feeders?

battery powered Printrbot Play