Massive amounts of support

Yeh I’m keeping them off for that reason

I like the idea, would save cleaning the bed & let you print straight away after a print finishes.

I’ve just received my Anycubic ultrabase a few days ago, stuff is amazing. Sticks solid during a print & auto releases when it cools.

I damn near need to use a hammer & chisel to get PETG off usually, but I just picked up the print like it had never been stuck.

How do you adhere it to the heated bed?

On the CR-10 I just use binder clips like normal. The one I got for my Delta is self adhesive though.

I’ll check it out thanks!

Because I don’t have one available, can I throw money at someone here to print me a few small parts? I’m looking at what I want built later this year.

Show me what you want printed and maybe we can work something out. My build area is 200 x 200 x 200 mm. I only have PLA though. Print quality on mine isnt the best but she gets the job done.

At the moment just some covers for laptop CD drive bays. But I will need some parts printed for knitting / sewing machines later this year so relatively small parts over all.

Is there a linux based modeling app that I can use to make these models?

You can use blender & export to .stl

Not the best program for accurate measurements, but it gets the job done.

If you use a browser that can use Onshape there is that

I’m pretty good with the autocads since its my job and all. With dimensions for your part I could make what you want from a crude 2d sketch.

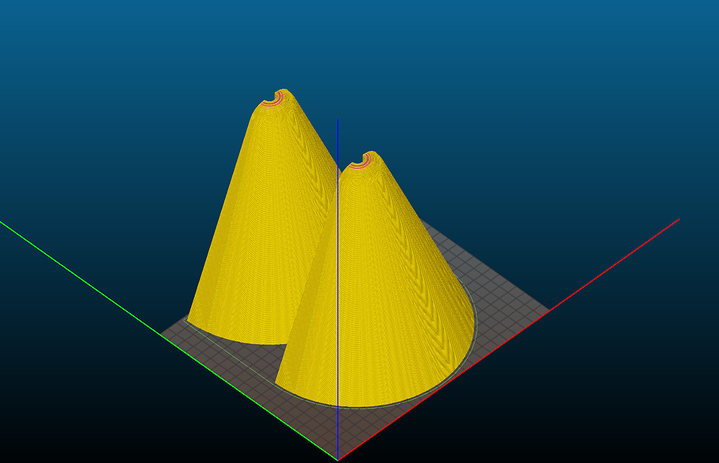

why not just rotate it on its edge so its printingin a horse shoe… no support required then.

edges have a radius, too little contact with the build plate

and adding support to that would ruin the the surface finish

Tinker cad is a browser based so should work in linux too… its what I use to design models.

They are really specific pieces it would be better for me to do it by hand.

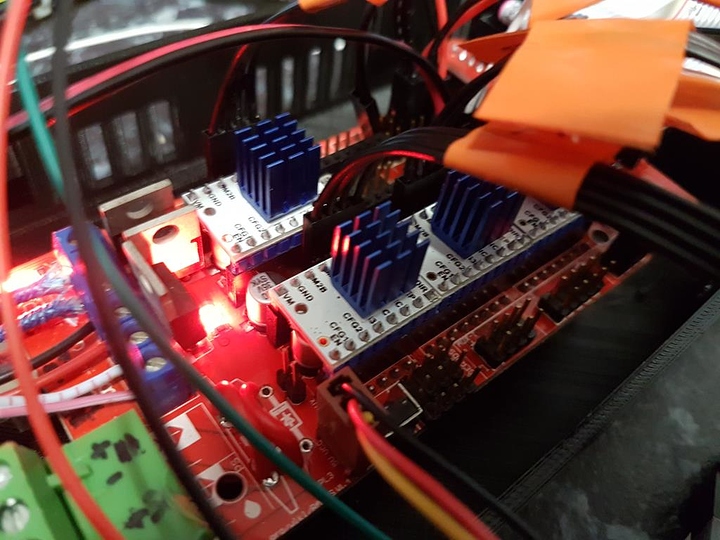

I must say, the TMC2100 stepper driver boards are pretty damn quiet! My stepper motors (well the ones in the printer, I don’t personally have any yet) are quieter than the fans on my printer now.

They are drop in replacements for the common A4988 drivers that most printers come with. I am not going to get in and do extreme configuration on them, I have other shit to do. All I did was put the heatsinks on, set the voltages to 0.8v using the pot, and started printing. Now my printer doesn’t sound like it is murdering a froggery of screeching peppes.

More informed people have made videos about them on youtube.

I got mine from gearbest:

Actual picture of literal stepper drivers really working.

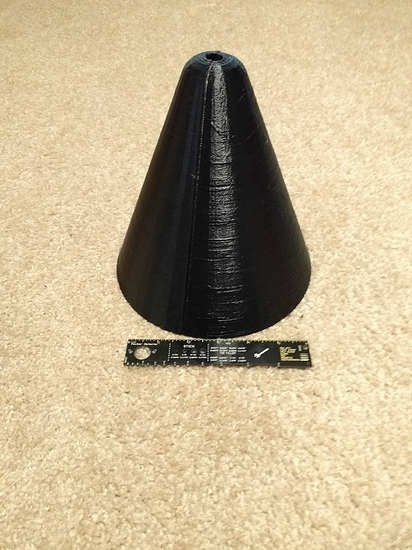

6 inch pecker detector for scale

meh, dad drew it of a guess

Hopefully squirrels wont get to it now, other option is shooting them but I’m not watching it all the time

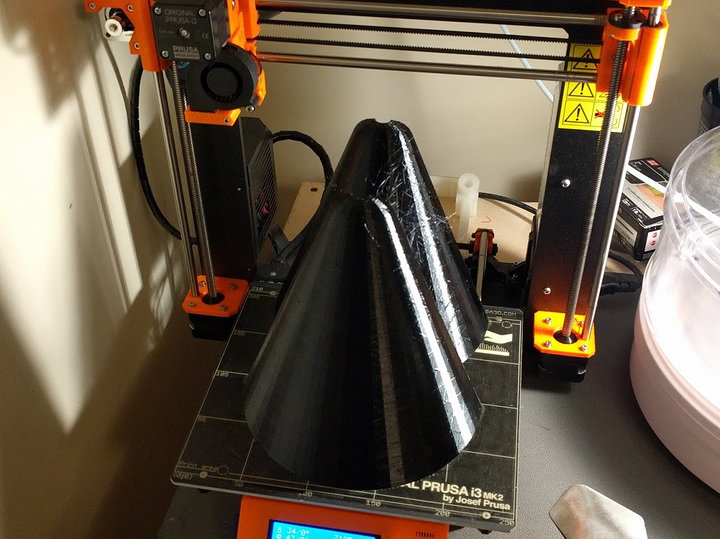

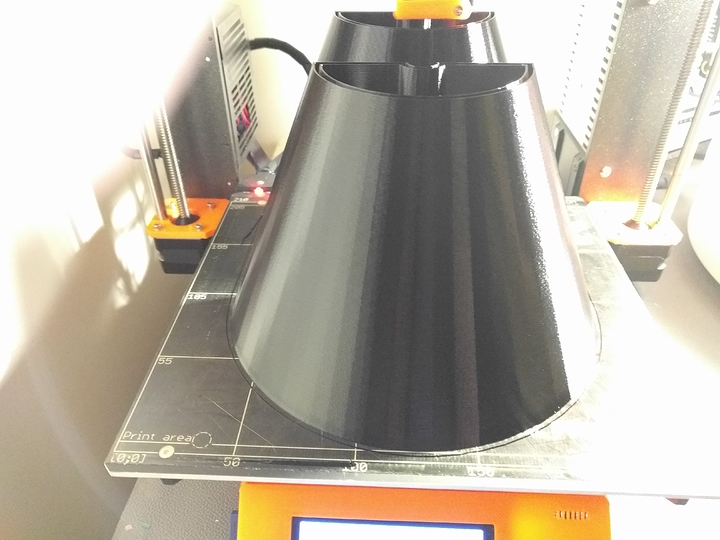

Reason for black PETG is that normally PETG is harmed by UV rays and I dont have any ASA so I am hoping that the black dyes in the filament will absorb more UV than the plastic

we shall see

Doing another version with no infill and 2 wall layers instead of 3 and zero infill, uses a lot less plastic and my gosh this surface finish

Why not a uv resistant clear coat?